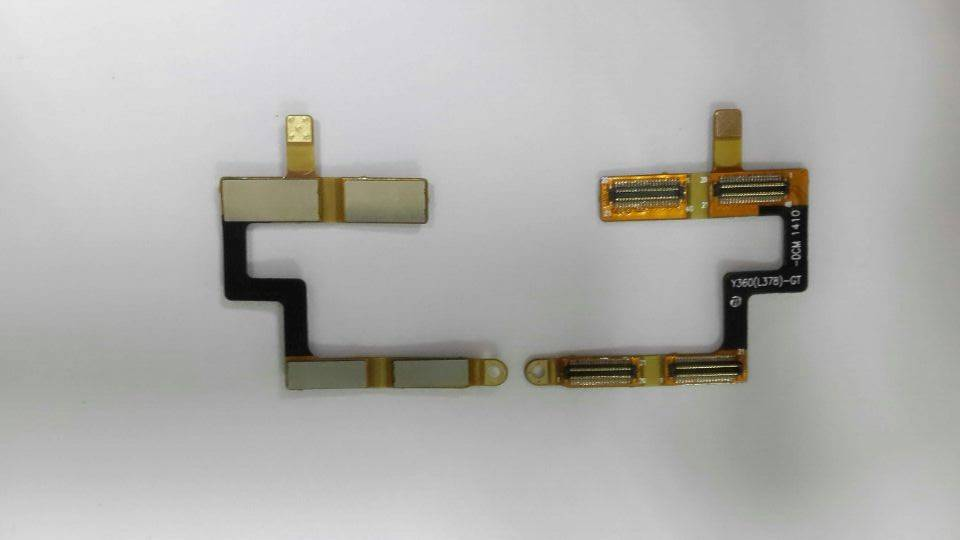

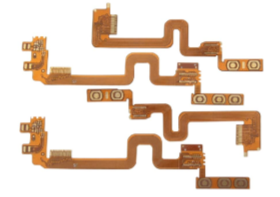

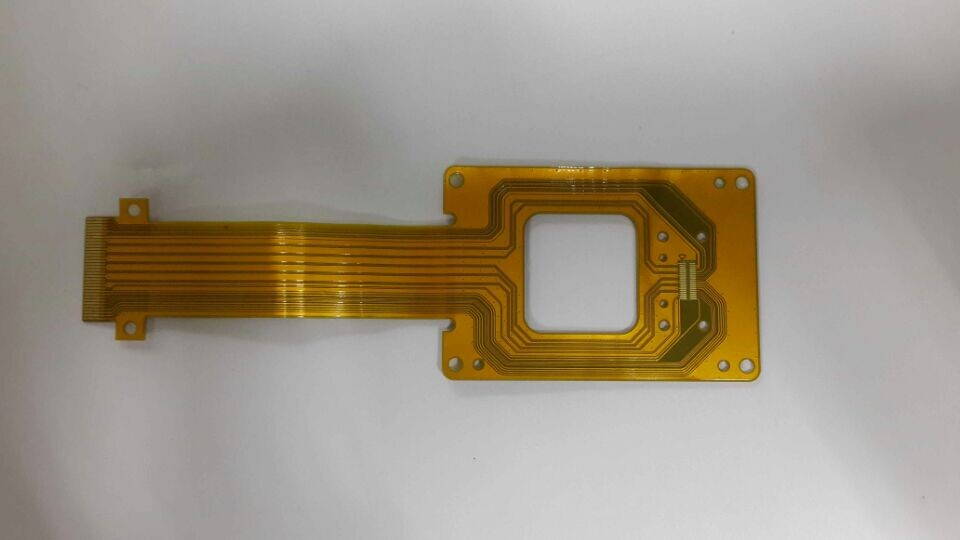

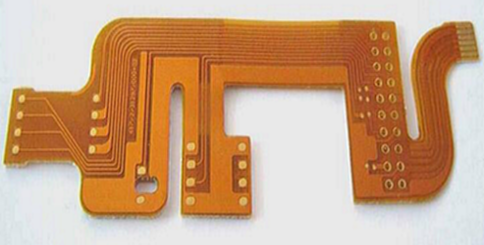

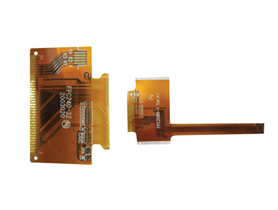

PCB type: FPC flexible circuit board

Number of layers: 2R 1F layers

Thickness of PCB: 0.6mmSurface treatment: Electroless gold plating

Minimum trace width/spacing: 8/8 mil

Introduction to three-layer rigid-flex printed circuit board (FPC PCB)

Basic concepts of flexible FPC and PCB boards

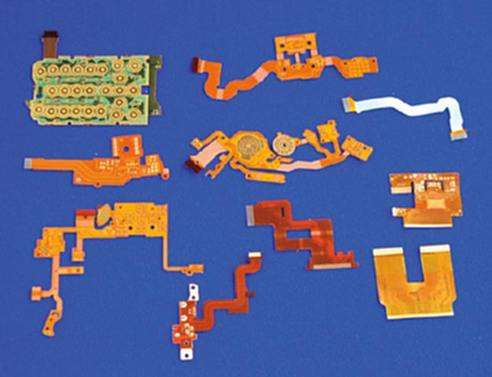

FPC (Flexible Printed Circuit) refers to a printed circuit board made of a flexible insulating substrate, also known as a flexible board or a soft board. In addition to using flexible materials, rigid-flex boards also use rigid materials. A three-layer rigid-flex FPC printed circuit board is a flexible multi-layer printed circuit board, which means it contains three conductive layers with plated through-holes and may or may not have a reinforcement layer. Its structural form is more complex than that of single-sided circuit boards and double-sided circuit boards, and the process quality is also more difficult to control.

Characteristics of three – layer rigid – flexible combined FPC printed circuit boards

Light, thin, short, and small.

The flexible substrate is composed of thin films. Compared with rigid printed circuit boards, it is more suitable for application in precision small electronic devices. Compared with rigid circuits, it can save 60% – 90% of the space and reduce the mass by about 70%.

Flexibility; pliability; elasticity; adaptability

“Flexibility” usually refers to the property of materials, objects, etc. that allows them to bend or flex. The word “flexibility” means “pliability; adaptability; bendability”, etc., and it is a more appropriate expression here.

It can achieve static and dynamic bending, and the number of bending times can reach 10⁷. It can be used in the main body of equipment with geometric shapes where rigid printed circuit boards cannot be installed, and also for connections between dynamic electronic components. Its light weight and flexibility can completely replace the bulky, thick, and rigid wire harnesses.

High assembly reliability and high yield

It reduces the hardware required for internal connections, such as solder joints, trunk lines, backplane circuits, and cables commonly used in traditional electronic packaging, thereby providing higher assembly reliability and yield.

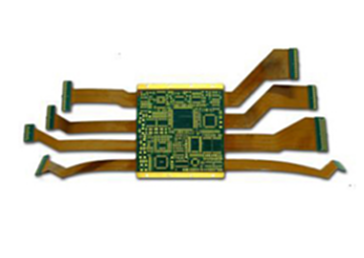

Three-dimensional interconnection device

It can be extended to three-dimensional space for three-dimensional (3D) interconnection installation, which improves the degree of freedom in circuit design and mechanical structure design and fully exploits the functions of the printed circuit board.

Outstanding performance; excellent capabilities (A more appropriate expression needs to be determined according to the specific context).

It has excellent electrical properties, dielectric properties, and heat resistance. A lower dielectric constant allows for the rapid transmission of electrical signals; good thermal properties make it easy to cool the components; a higher glass transition temperature or melting point enables the components to operate well at higher temperatures. In addition, planar conductors have a larger area-to-volume ratio than circular conductors, which is beneficial for heat diffusion in the conductors, and the shorter heat paths further enhance the heat diffusion.

Three-layer rigid-flex printed circuit board (FPC) material

Note: Generally, there’s no need to translate “PCB” and “FPC” repeatedly here. This is because “FPC” is actually a special type of “PCB” (Printed Circuit Board). “Rigid-flex combination” refers to the design method of combining rigid and flexible parts. “Flexible Printed Circuit Board” is a common way to refer to “FPC”.

Flexible materials

-

Flexible copper-clad substrate: Its basic structure includes insulating base film materials, adhesives, and copper foils. Commonly used insulating base film materials are polyimide, polyester, and polyfluoride. Among them, polyimide films and polyester films are currently the mainstream materials in the production of flexible printed circuit boards. For example, polyimide (PI) film is yellow and transparent, with a relative density of 1.39 – 1.45 g/cm³. It has excellent high-temperature resistance, radiation resistance, and chemical corrosion resistance, high dielectric strength, and excellent electrical and mechanical properties. It can be used in air at 250 – 280°C for a long time, but it is expensive and has high hygroscopicity. The PET dielectric film produced by DuPont – Mylar film is also commonly used.

-

Flexible bonding film: Used for interlayer bonding, etc.

-

Cover film: It serves the purpose of protecting circuits, etc.

-

Reinforcing materials: Can be added as needed to enhance certain properties of the board.

Rigid materials

For example, epoxy glass cloth laminates and their prepregs, or polyimide glass cloth laminates and the corresponding prepregs.

Price reference for three-layer rigid-flex FPC printed circuit boards

The prices of three – layer rigid – flex FPC PCB boards from different manufacturers and with different specifications vary greatly. According to the information on Baidu Aigou, there are different pricing methods for rigid – flex boards. For example, some are priced by set (such as the products of Shenzhen Tengnan Industrial Co., Ltd., with a selling price of 200,000 yuan per set), and some are priced by piece (such as the products of Guangdong Zhengye Technology Co., Ltd., with a selling price of 12.65 yuan per piece). However, the specific price of the three – layer rigid – flex FPC PCB board still needs to be determined through negotiation with the manufacturer based on the actual size, thickness, process requirements, etc.

Related to the lamination technology of three-layer rigid-flex FPC printed circuit boards.

Wire bonding technology (also known as wire bonding – COB (Chip on Board) technology) refers to a technology that directly attaches a bare chip to a printed circuit board (PCB) and then uses aluminum or gold wires for electrical connection. Flexible printed circuit (FPC) products also have an urgent need for wire bonding technology. However, due to the significant differences in their manufacturing materials and processing techniques compared with printed circuit boards, after the FPC products are made, the wire bonding performance test is different from that of PCB products, and the manifestations of wire bonding defects also vary greatly. When producing three – layer rigid – flexible combined FPC printed circuit boards, wire bonding performance problems such as low wire bonding passing rate and poor wire bonding reliability (mainly manifested as wire bonding adhesion) may also be encountered, which need to be improved according to their material characteristics and processing techniques.

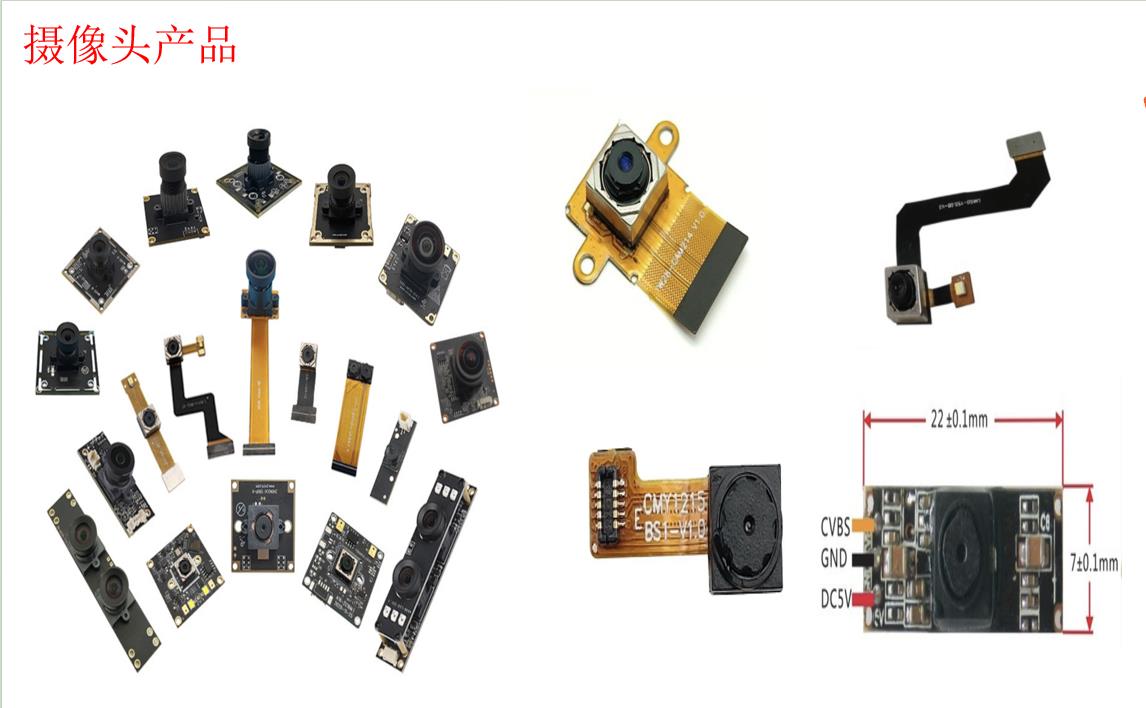

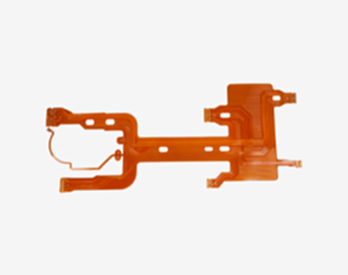

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

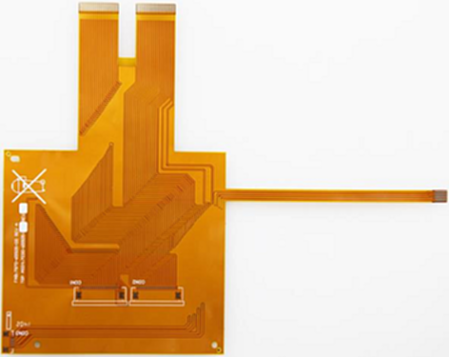

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

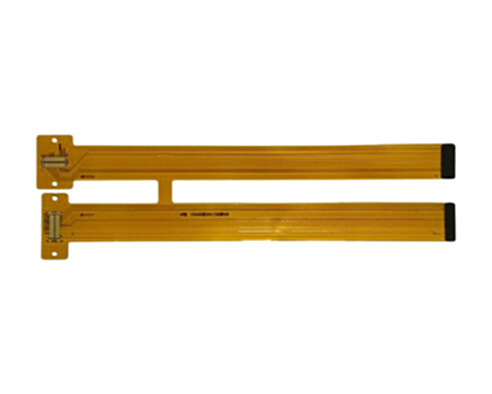

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

10-layer flexible FPC fingerprint circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer flexible FPC fingerprint circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More