Product Overview

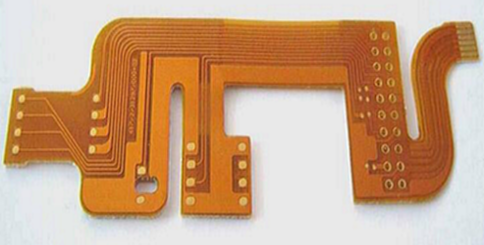

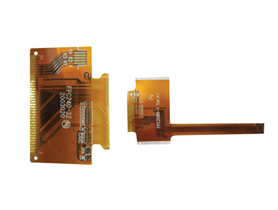

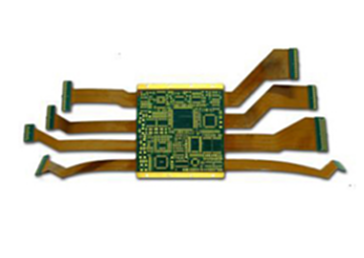

FPC (Flexible Printed Circuit Board) is a type of printed circuit board made from flexible base materials and featuring graphics, consisting of insulating base materials and conductive layers Impedance FPC boards, on the other hand, are FPC boards with specific requirements for characteristic impedance. At a certain frequency, the resistance encountered by high-frequency signals electromagnetic waves during transmission in electronic device transmission lines, relative to a reference layer, is referred to as characteristic impedance. It is a vector sum of resistance, inductance, and capac.

Product Types

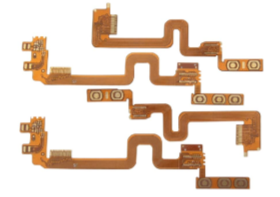

The company specializes in the production and sale of various types of FPC flexible circuit boards, including FPC ribbon cables, modules, back, capacitive touch screens, multilayer stratified, buttons, antennas, battery protection boards, etc.

Product Characteristics

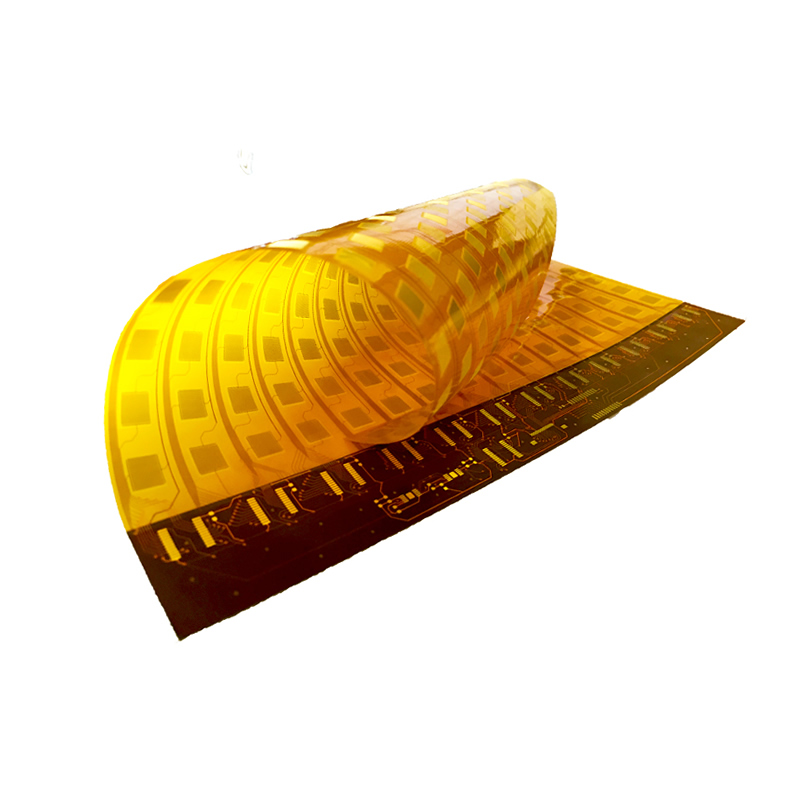

Physical Characteristics Maximum processing can reach 250mm x 1200mm; minimum line width and spacing of 0.05mm/0.05mm (2mil2mil); etching tolerance of ±0.5mil; exposure registration tolerance of ±0.05mm (2mil); PI film registration tolerance <0.10 (4mil); minimum line spacing of 0.075 – 0.09MM; minimum drill hole diameter of 0.1mm; base material copper thicknesses of 18μ (1/2OZ), 35μ (1OZ), 70μ (2OZ), etc. reinforcement and adhesive film registration tolerance <0.1mm (4mil); polyimide/polyester base material thicknesses of 0.025mm – 0125mm.

Performance Characteristics It has excellent bending resistance and chemical resistance, conforming to international printed circuit FPC standards; solder resistance of 105280 – 360; insulation resistance between 50Ω – 120Ω; thermal shock resistance of 85 – 105℃280℃ – 360℃; finished boards have certain bending resistance and peel strength, suitable for different types such as single-sided boards, double-sided boards multilayer boards, and rigid-flex boards.

Product Uses

FPC ribbon cables have a certain degree of flexibility and are used to connect related parts products. They have been widely used in many products such as photocopiers and laptops. In addition, impedance FPC boards are widely used in automotive navigation, beauty devices, LCD, and other fields, providing stable signal transmission and electrical connection solutions for various electronic devices.

Production Manufacturing

(a) Production Process

Material Selection: There are types and production processes for FPC materials, including electroplated copper, rolled copper, with and without glue, etc. When choosing substrates for high-frequency PCBs, special should be paid to the DK characteristics of the materials under different frequencies; for requirements that focus on high-speed signal transmission or characteristic impedance control, DF and its performance under such as frequency, temperature, and humidity should be examined. General-purpose substrate materials exhibit different performance when the frequency changes.

Process Flow

Material input: The type of board, board thickness, and copper foil thickness must be produced according to MI requirements.

Special requirements: Impedance boards should not be produced by pressing the core board by themselves or micro-etching the copper surface.

Key process control: For example, when increasing the number of bends, special control is required during the production, especially during the electroating copper process.

Production Equipment and Technology

The company has advanced production equipment and a professional technical team. For example, in the production of multilayer differential characteristic FPC, a processing device for multilayer differential characteristic impedance FPC production is used. The

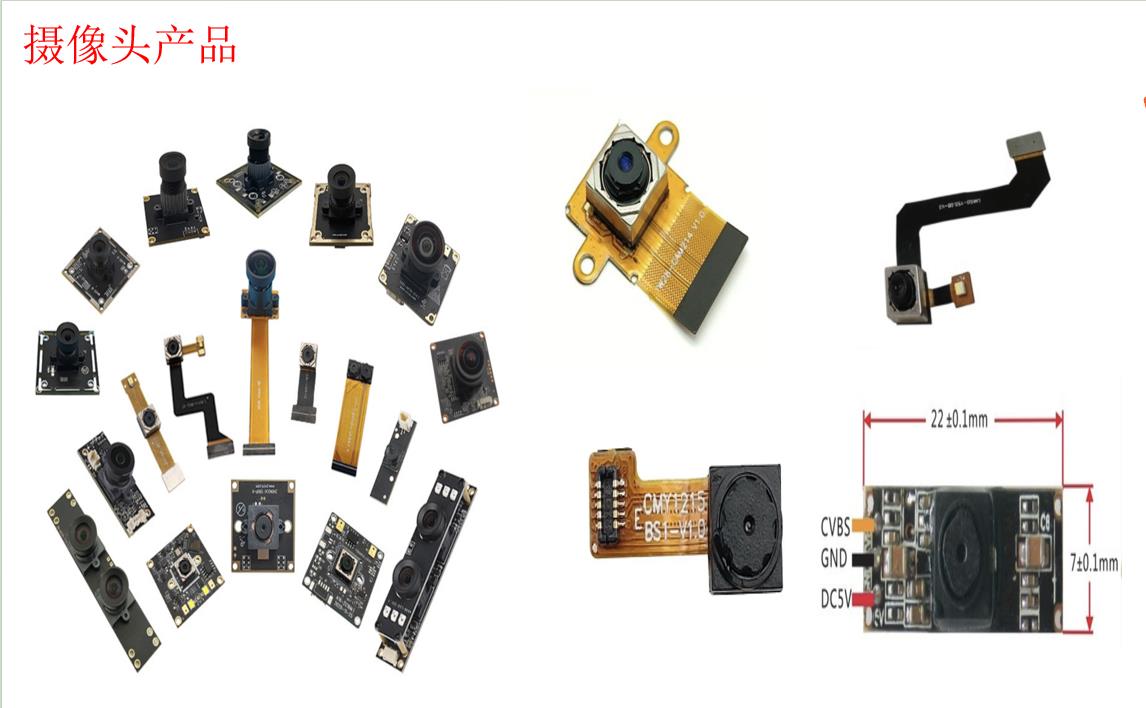

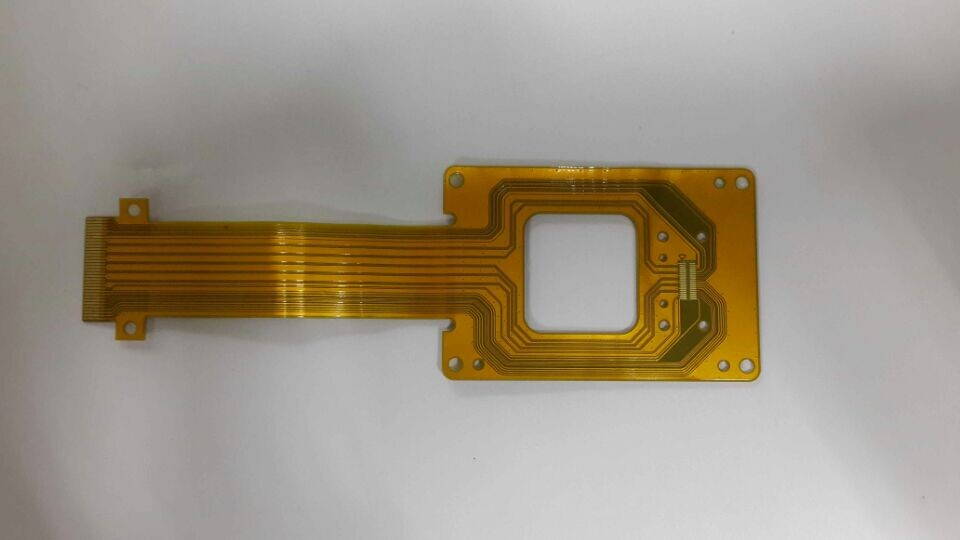

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

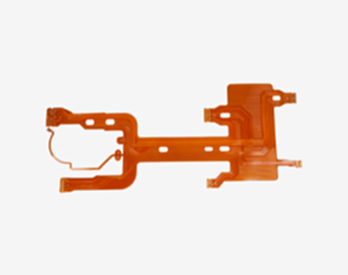

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

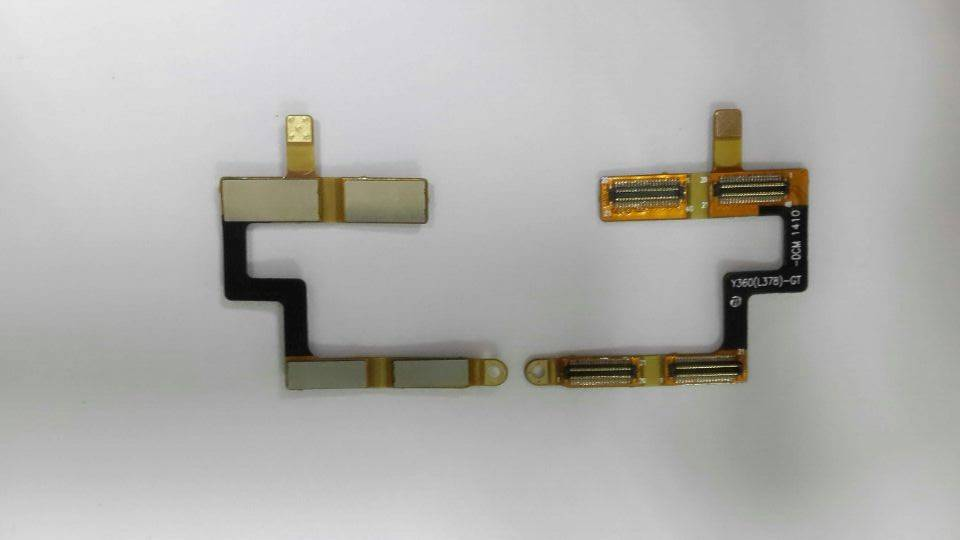

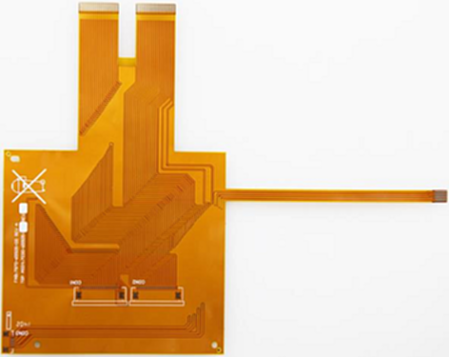

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

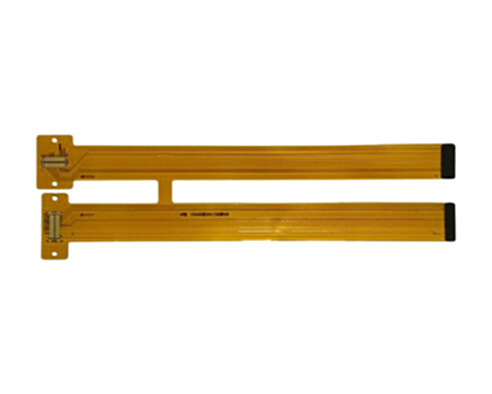

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More

Common knowledge of circuit boards: Composition and main functions of some parts of circuit boards

Common knowledge of circuit boards: Composition an…

Read More

Common knowledge of circuit boards: Composition and main functions of some parts of circuit boards

Common knowledge of circuit boards: Composition an…

Read More