Overview of FPC protection boards for new energy lithium batteries

Definition and structure of FPC protection board

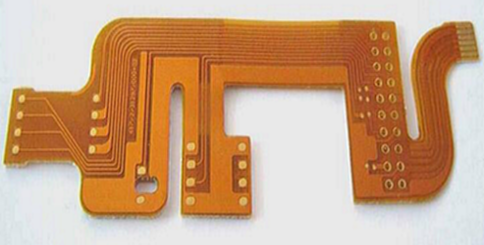

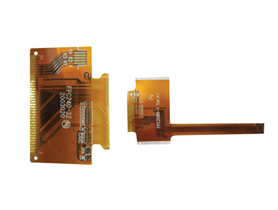

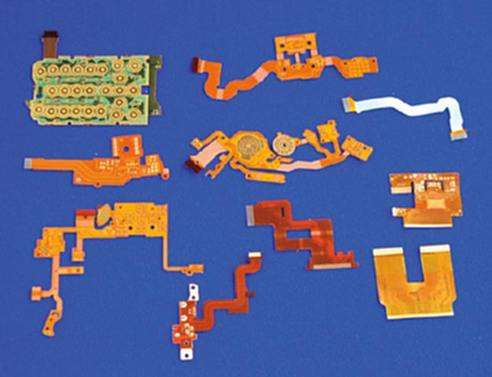

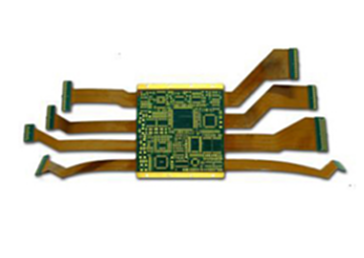

FPC, namely flexible printed circuit board, is a circuit board manufactured with flexible copper-clad laminate as the base material and can be divided into various types such as single-layer, double-layer, multi-layer and rigid-flex boards. The FPC protection board for new energy lithium batteries applies FPC technology to lithium battery protection boards and may integrate multiple elements such as FPC, plastic structural parts and copper-aluminum busbars. For example, the gradually developing CCS (Cells Contact System, integrated busbar, wiring harness board integrated component) product realizes the series and parallel connection of multiple battery cells through laser welding. This integrated design not only improves the reliability of electrical connections but also further optimizes the signal detection structure.

The role of the FPC protection board in new energy lithium batteries

Data collection and transmission

In the BMS (Battery Management System) of new energy vehicles, the acquisition line is an important component. The FPC protection board can be used as an acquisition line, which is responsible for monitoring the voltage and temperature of the power battery cells, realizing data acquisition and transmission, and has an over – current protection function. It plays a key role in protecting the power battery cells of vehicles and automatically disconnecting in case of abnormal short – circuits.

Ensure the safety and performance of the battery.

The lithium battery protection board is used for the charge and discharge protection of the series-connected lithium battery pack. When the battery pack is fully charged, it can ensure that the voltage difference between each single battery is less than the set value (usually ±20mV), realizing the equalization charging of each single battery in the battery pack and effectively improving the charging effect under the series charging mode. At the same time, it can also detect the over – voltage, under – voltage, over – current, short – circuit, and over – temperature states of each single battery in the battery pack, protecting and prolonging the service life of the battery. The under – voltage protection prevents each single battery from being damaged due to over – discharge during the discharge process.

Advantages of FPC protection boards compared to traditional copper wire harnesses

Design and layout advantages

-

Highly integrated: With self-embedded fuses, connectors, chip NTCs, aluminum/nickel terminals, etc., it not only provides excellent and consistent electrical performance, but also can meet the design requirements for smaller and higher-density installations. The wiring and appearance can be changed according to the space limitations, making it suitable for the development needs towards high density, miniaturization, and high reliability.

-

Ultra-thin thickness and ultra-softness: It has outstanding advantages in terms of safety, lightweight design, and regular layout, and can be customized according to the battery pack structure.

Production advantages

- High degree of automation: In the Pack assembly stage of the traditional copper wire harness solution, workers are required to manually fix the ports onto the battery pack, resulting in a relatively low degree of automation. In contrast, the FPC protection board can be directly placed by robotic arms during assembly, enabling highly automated production, which is very suitable for large-scale mass production.

Market application situation

Around 2017, due to the small – batch and high – cost nature in the early stage of the industry and the strict requirements for reliability in the automotive electronics field, most power battery enterprises adopted a wait – and – see attitude towards FPC. However, with the excellent performance of FPC and the cost reduction brought about by large – scale production, the process of its replacing traditional wiring harnesses has significantly accelerated. According to a 2018 survey by GGII, leading domestic power battery enterprises such as CATL and BYD have applied FPC in batches in the Pack process. In addition, well – known enterprises such as Tesla, Guoxuan High – tech, AVIC Lithium Battery, Taifel, Sunwoda, and Farasis have also started to use FPC. Currently, the FPC solution has become the first choice for the vast majority of new new – energy vehicle models.

Market prospects

The market has great growth potential.

With the booming development of markets such as new energy vehicles, energy storage systems, and portable electronic devices, the lithium battery protection board market has ushered in unprecedented growth opportunities. According to data from market research institution QYResearch, it is estimated that by 2030, the global lithium battery protection board market size will reach US$2.42 billion, with a compound annual growth rate (CAGR) of 3.4% in the next few years. This also brings broad market prospects for the FPC protection boards of new energy lithium batteries.

Technological innovation drives development.

With the application of new materials, new processes, and new technologies, the performance, safety, reliability, etc. of lithium battery protection boards have been continuously improved. For example, high-precision sensors and intelligent algorithms are used to achieve more accurate battery status monitoring and early warning functions; new electronic components and PCB board materials are used to improve the reliability and stability of products. These technological innovations will also promote the new energy lithium battery FPC protection board industry to develop to a higher level.

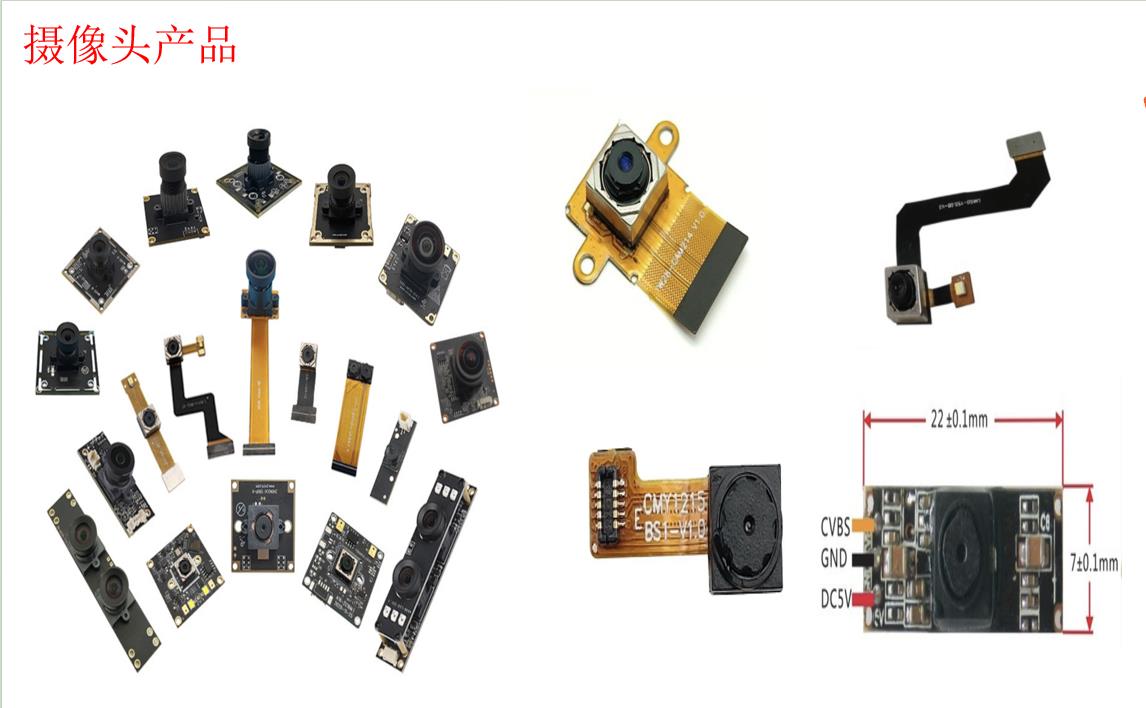

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

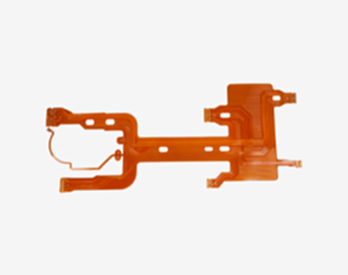

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

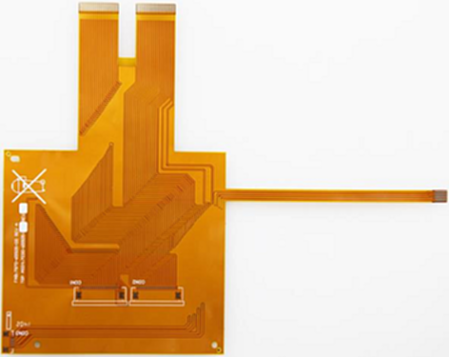

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

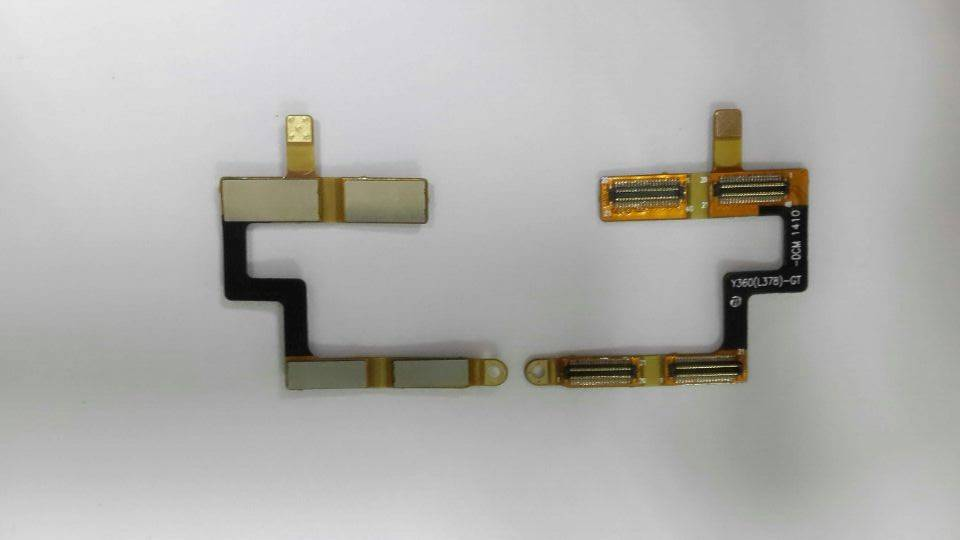

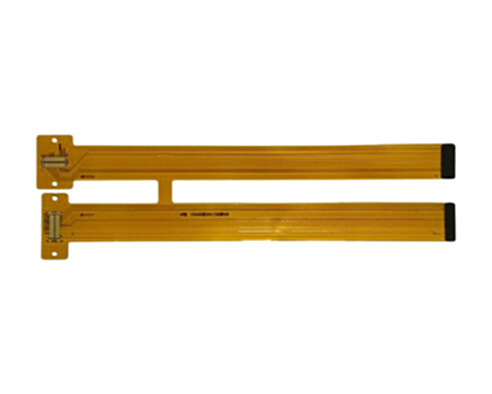

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

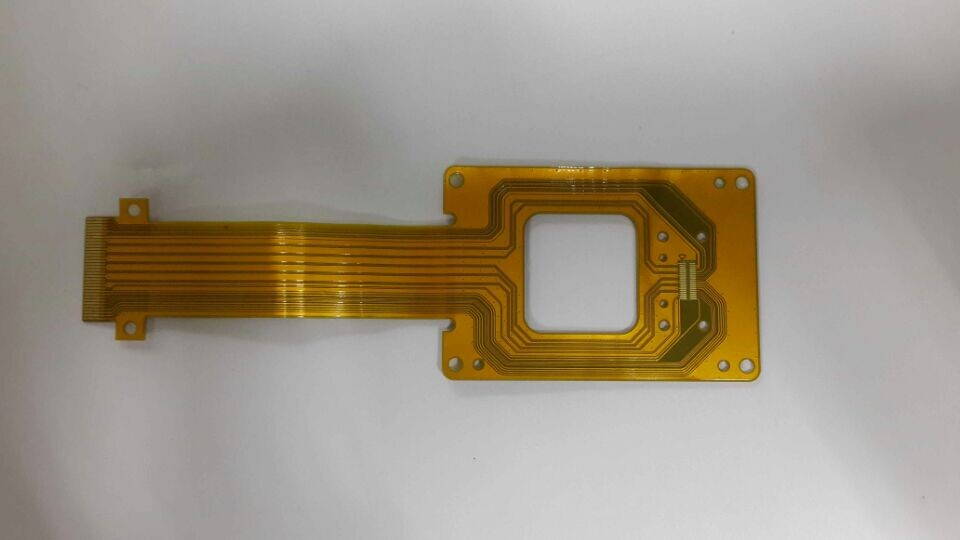

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

10-layer flexible FPC fingerprint circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer flexible FPC fingerprint circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More