Service Advantage

- ✅ Quick Response: 24-hour technical consultation, sample delivery as fast as 5.

- ✅ Cost Optimization: Flexible selection of domestic/imported materials, mass production cost reduction of 30% .

- ✅ Full Control: Real-time tracking production progress with ERP system, supporting customer factory inspections.

- ✅ Long-term Cooperation: Signing of NDA agreements, ensuring intellectual property rights and data security.

-

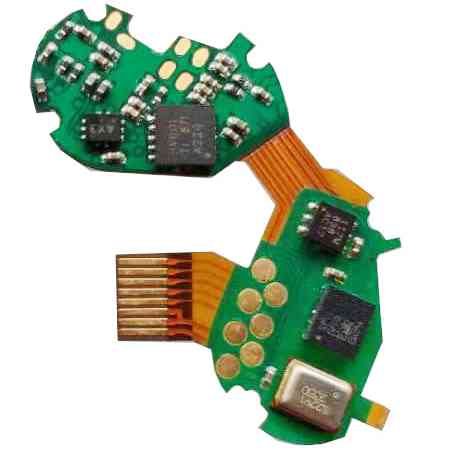

Flex PCB Prototype

- 1 - 16 Layers

- 1 - 10000

- Rolled copper/electrolytic copper

- PI, PET, etc.

- 6um-100um

- 0.01mm-0.1mm

- 24Hours - 3weeks

- Quote Now

-

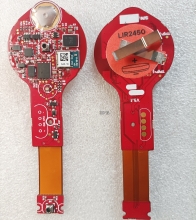

Flex PCB Prototype

- 1 - 16 Layers

- 1 - 10000

- Rolled copper/electrolytic copper

- PI, PET, etc.

- 6um-100um

- 0.01mm-0.1mm

- 24Hours - 3weeks

- Quote Now

-

Flex PCB Prototype

- 1 - 16 Layers

- 1 - 10000

- Rolled copper/electrolytic copper

- PI, PET, etc.

- 6um-100um

- 0.01mm-0.1mm

- 24Hours - 3weeks

- Quote Now