FPC Prototyping Service Process

1. Requirements Communication

Clients contact our business team and provide FPC design requirements, including detailed specifications such as circuit schematics, layout diagrams, dimensional requirements, layer count, conductor materials, insulating materials, connection methods, etc. Our sales team will thoroughly understand and document the requirements, then confirm their accuracy and completeness with the client.

2. Design Evaluation

Our expert engineering team conducts a detailed analysis and feasibility assessment of the client’s design files. If any issues or potential risks are identified, we promptly communicate with the client and provide optimization suggestions to ensure a smooth implementation of the design.

3. Material Selection

Based on the design requirements, our material specialists carefully select suitable conductive materials, insulating substrates, and base materials. Since material choice directly impacts FPC performance and cost, we prioritize optimal solutions that balance performance and cost-effectiveness.

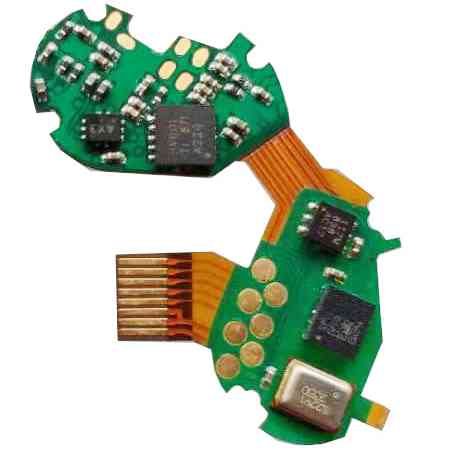

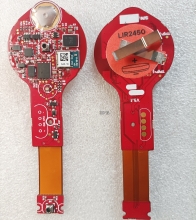

4. Prototyping

Once the design and materials are finalized, our production team immediately initiates FPC prototyping. Using advanced manufacturing processes and equipment, we precisely control each step—including drilling, chemical etching/laser cutting of conductive layers, lamination, and overlay bonding—to ensure the FPC meets design specifications in both quality and precision.

5. Inspection & Testing

After prototyping, all samples undergo rigorous inspection and testing, including:

- Visual inspection

- Electrical performance testing

- Functional validation

Only samples that pass all tests proceed to the next stage.

6. Delivery & Feedback

Qualified FPC prototypes are delivered to the client, and their feedback is collected. We highly value client input and continuously refine our services to enhance quality and satisfaction.

Applications

Our FPC prototyping services are widely used in:

- Consumer Electronics: Smartphones, tablets, wearables

- Medical Devices: Diagnostic equipment, implantable devices

- Smart Home & IoT: Sensors, AI-driven appliances

With the rapid growth of IoT and AI technologies, FPC applications continue to expand. We constantly upgrade our capabilities to meet evolving industry demands.

Cooperation Models

Long-Term Partnership

We encourage long-term collaborations through formal agreements, which define responsibilities and benefits. Clients enjoy:

- Cost Sharing: Reduced per-unit prototyping expenses.

- Joint R&D: Technical and market synergy for mutual growth.

Project-Based Cooperation

For short-term needs, we offer flexible project-based solutions with customized prototyping plans and budgets tailored to specific requirements.

Our Commitment

We are dedicated to delivering high-quality, efficient, and professional FPC prototyping services, striving to be your most trusted partner.

Contact us today to discuss your FPC needs!

Key Features:

- Technical Accuracy: Industry-standard terms (e.g., “laser cutting,” “rigid-flex”).

- Clarity & Flow: Logical progression mirroring the Chinese version.

- Marketing Tone: Emphasis on partnership and responsiveness.

- Localization: “IoT/AI” instead of direct translations for broader appeal.

Let me know if you’d like to adjust any section for specific audiences (e.g., EU/US clients)!