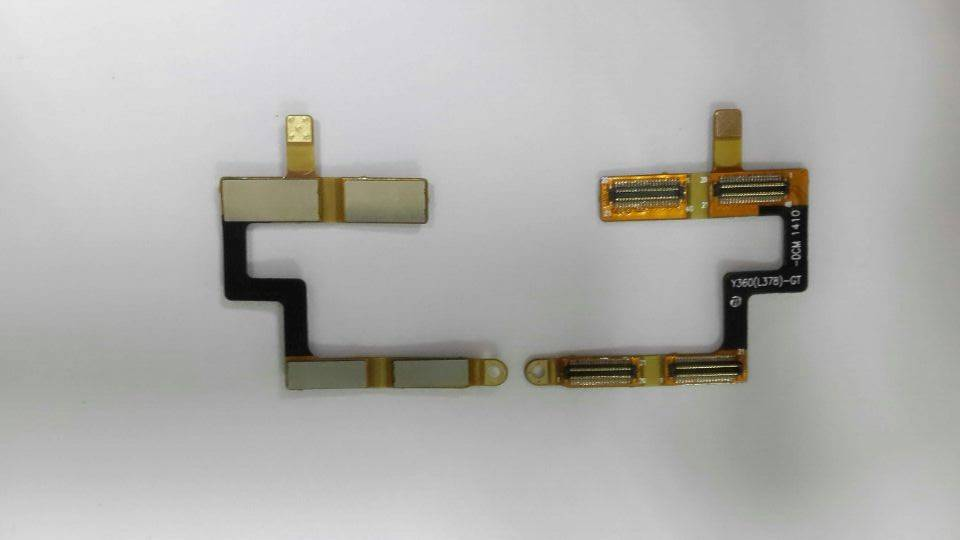

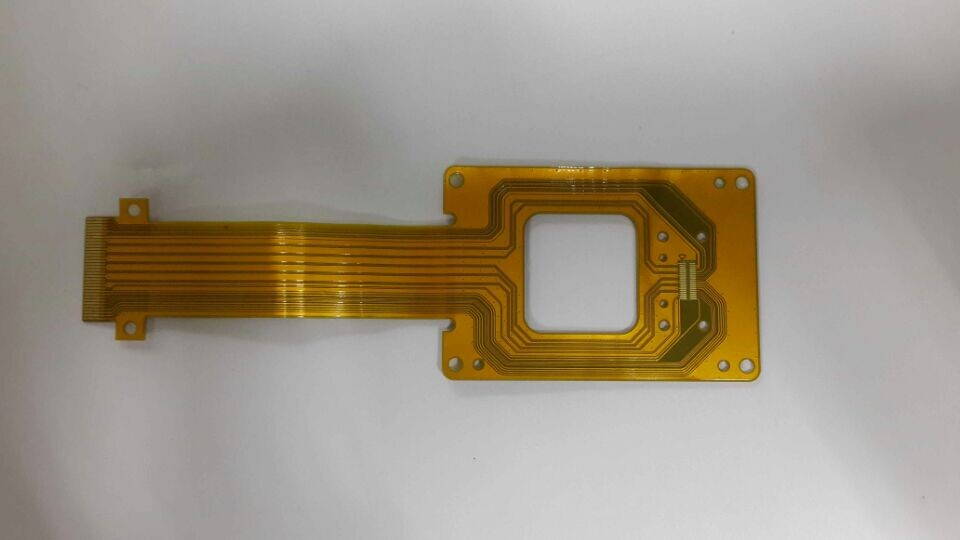

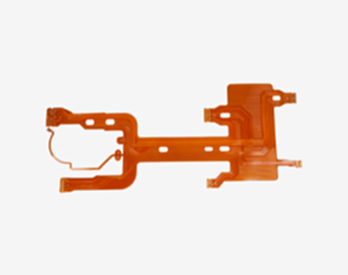

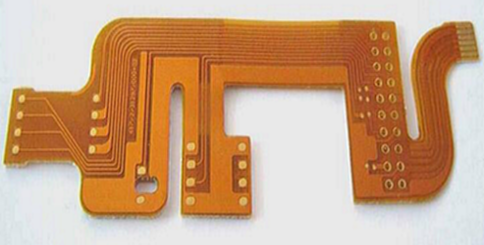

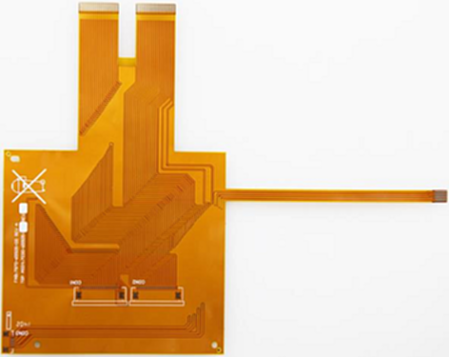

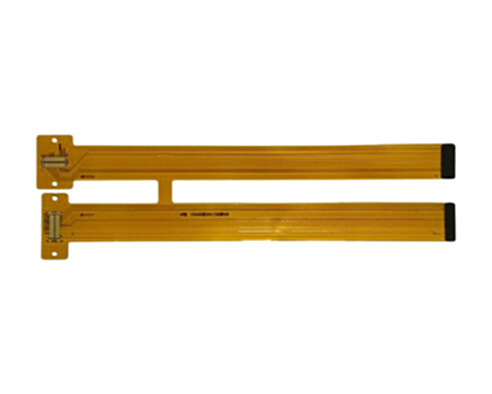

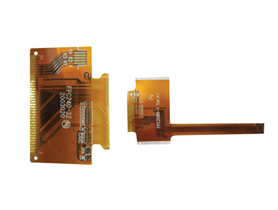

Overview of double-sided FPC cable

Double-sided FPC cable is a type of cable. The cable is also called flexible printed circuit (FPC). It is composed of a flexible substrate and a conductive layer, has the ability to bend and fold, and is suitable for various complex electronic devices and systems.

Basic information

Definition and Composition

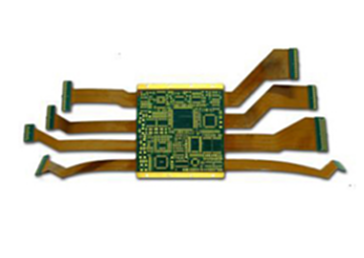

Double-sided FPC cable is a flexible printed circuit board with double-sided conductive traces. Conductive traces are arranged on both sides of the flexible substrate, and the electrical connection between the traces on both sides is achieved through methods such as via holes.

Main parameters

-

Substrate thickness: Generally between 0.025 mm and 0.125 mm.

-

Minimum aperture: Usually ¢0.30mm ± 0.02mm.

-

Copper foil thickness: Common ones are 0.009 mm, 0.018 mm, 0.035 mm, 0.070 mm, 0.010 mm, etc.

Characteristics

-

Flexible and foldable: It can be freely bent, wound, and folded, and can withstand ten million times of sliding, which can meet the requirements of various complex space layouts and device design needs.

-

Compact Size: The flexible flat cable has a small volume and light weight. Its total weight and volume are reduced by 70% compared with the traditional round wire harness method, making it an effective solution to meet the requirements of miniaturization and mobility.

-

Convenient to use: It has extremely high softness and can be used flexibly. It is beneficial for transportation and storage and can also reduce costs.

-

Reliable electrical connection: It can provide a stable and reliable electrical connection in electronic devices, ensuring the stability of data transmission.

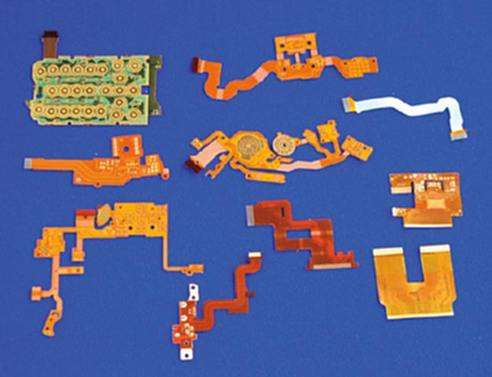

Application fields

Consumer electronics field

It is widely used in portable electronic products such as smartphones, tablets, and wearable devices. For example, it is used to connect key components such as the mobile phone motherboard, display screen, camera module, and touch screen. It can not only provide reliable electrical connections but also adapt to the shape and size changes of the devices to meet the requirements of high-speed data transmission.

Other high-tech fields

It is also widely used in fields such as computers, communication equipment, and precision instruments, realizing electrical connections between different components in these devices.

Precautions for production and processing

Route design

Since the FPC will expand due to temperature and pressure during ACF crimping, the expansion rate of the crimping fingers needs to be considered and pre – compensation treatment should be carried out when designing the circuit initially.

Typesetting design

Design the products to be distributed as evenly and symmetrically as possible throughout the layout. Keep the minimum interval between every two PCS products above 2MM. Try to stagger the copper-free parts and the parts with dense vias to reduce the impact of material expansion and contraction during the subsequent manufacturing process.

Solder paste printing

Since the FPC is loaded on the pallet and there is high-temperature-resistant tape for positioning on the FPC, which makes the height inconsistent with the pallet plane, an elastic scraper must be selected during printing. At the same time, a suitable solder paste should be selected because the composition of the solder paste has a great influence on the printing effect.

Mounting equipment

-

The solder paste printer should preferably be equipped with an optical positioning system; otherwise, the soldering quality will be significantly affected.

-

The FPC is fixed on the pallet, but there will always be some tiny gaps between the FPC and the pallet, which is quite different from the PCB substrate. Therefore, the setting of equipment parameters will have a significant impact on the printing effect, placement accuracy, and soldering effect.

Market situation

Manufacturers producing FPC flexible cables (including double-sided FPC flexible cables) are mainly concentrated in the Pearl River Delta region. With the continuous promotion of industrial transformation and upgrading, the penetration rate of products such as FPC rigid-flex boards, FPC multi-layer boards, FPC flexible circuit boards, FPC test boards and flexible cables is expected to continue to increase in the future. As an important product among them, double-sided FPC flexible cables will also迎来更广阔的发展空间。

注:“迎来更广阔的发展空间”可表达为 “usher in broader development space” ,完整译文如下:

Manufacturers producing FPC flexible cables (including double-sided FPC flexible cables) are mainly concentrated in the Pearl River Delta region. With the continuous promotion of industrial transformation and upgrading, the penetration rate of products such as FPC rigid-flex boards, FPC multi-layer boards, FPC flexible circuit boards, FPC test boards and flexible cables is expected to continue to increase in the future. As an important product among them, double-sided FPC flexible cables will also usher in broader development space.

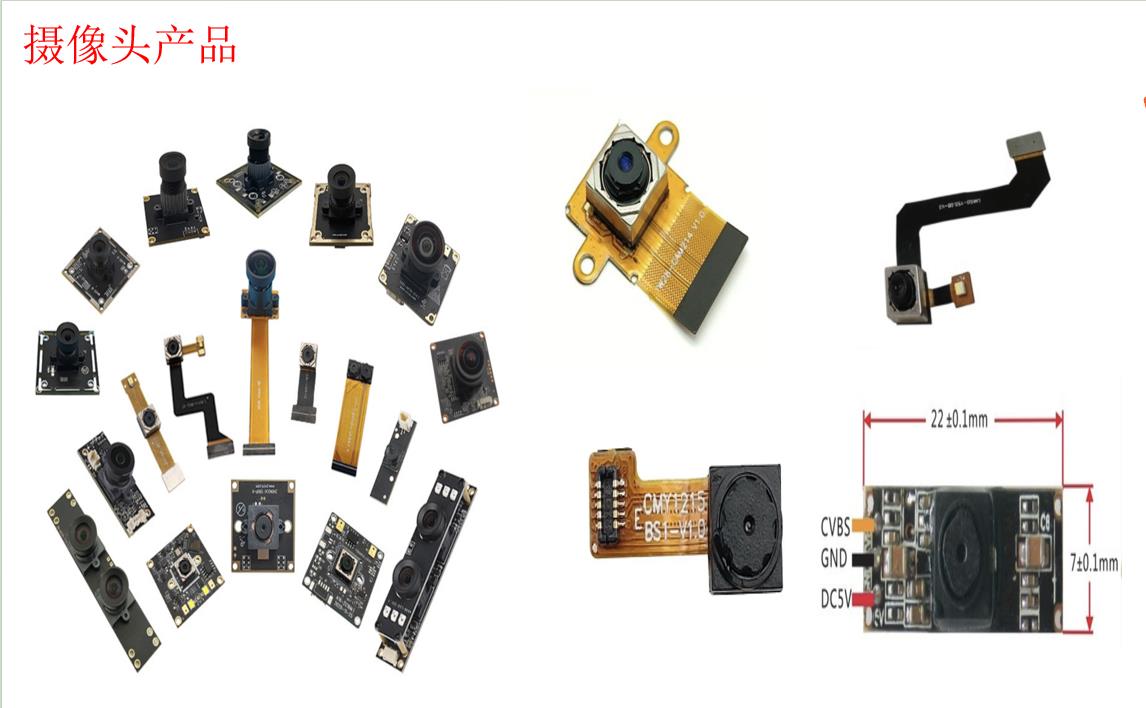

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

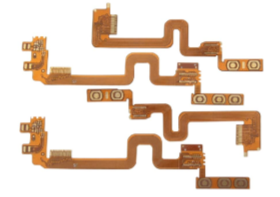

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

10-layer flexible FPC fingerprint circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer flexible FPC fingerprint circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More