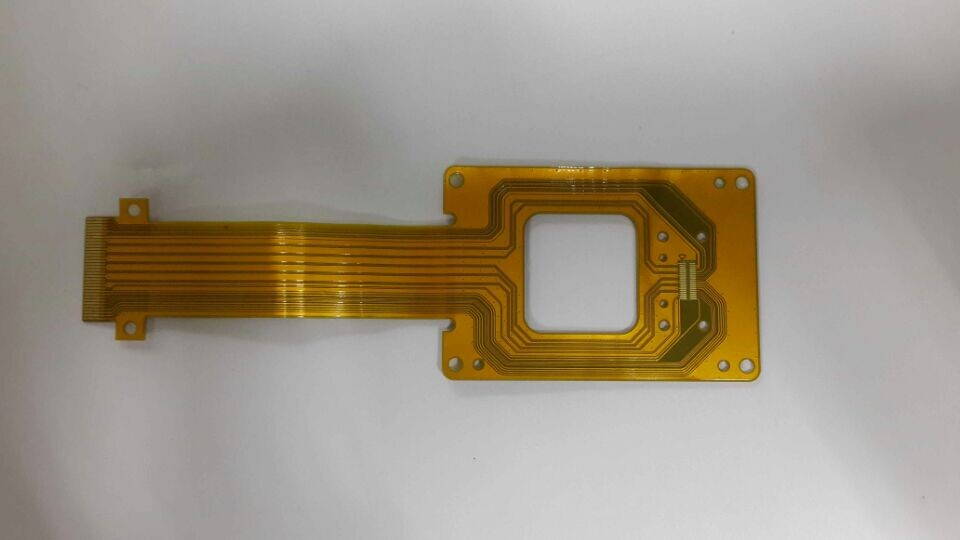

Introduction to large-size thick-copper double-sided flexible printed circuit boards

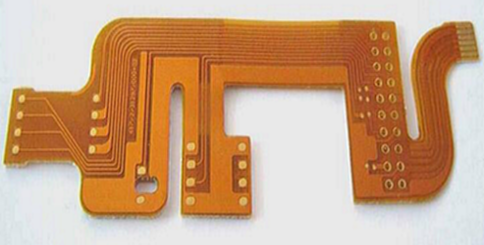

Definition and characteristics

Large-size thick-copper double-sided flexible boards are a special type of flexible printed circuit (FPC). “Large size” means that they have a relatively large area, which can meet some application scenarios that require a larger wiring space. “Thick copper” indicates that the copper foil is thick. Usually, thick-copper flexible boards can carry a larger current and have better electrical conductivity and heat dissipation performance. “Double-sided” means that there are conductive circuits on both the front and back sides of the circuit board.

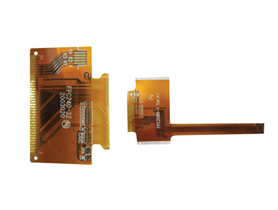

Examples of relevant products in the market

1.5OZ copper thickness single-sided, double-sided and multi-layer FPCB flexible printed circuit boards

The products of this kind produced by Shenzhen Longxiang Circuit Co., Ltd. can have a maximum size of 10×45 (250x1200mm), with a copper foil thickness of 0.5 – 3oz, featuring certain characteristics of large size and thick copper. The thinnest finished board can reach 0.08mm, the insulation resistance is ±1011Ω (Normal), the thermal shock resistance is 260℃ for 10 seconds, and the processing materials include polyimide (PI), polyester (PET), polyimide (PI) + FR4, etc.

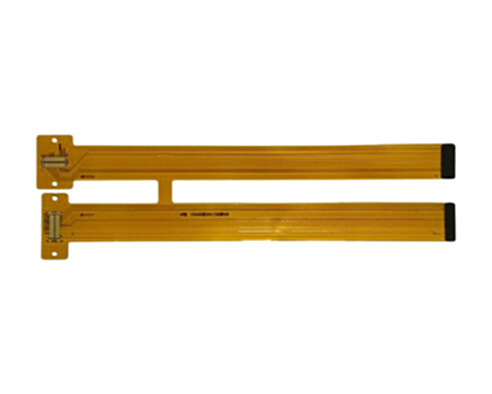

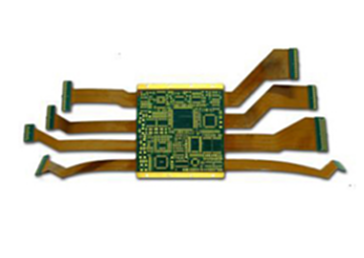

2OZ copper thickness, 680mm ultra-long flexible printed circuit board

The product sold directly from Jiangmen FPC flexible circuit board suppliers has a length of 680mm, which can be regarded as an indication of large size in terms of length. The copper thickness is 2OZ, and it can be used for panel lights (square) FPC flexible circuit boards, 2835 flexible light strips, etc.

Application fields of large-size thick copper double-sided flexible boards

Communication equipment

In some large-scale communication base station equipment or communication terminals that require high-speed data transmission, large-sized thick-copper double-sided flexible boards can provide sufficient wiring space to achieve complex circuit connections. Meanwhile, the thick-copper design can ensure stable signal transmission and good heat dissipation, meeting the requirements of communication equipment for stability and reliability.

Automotive electronics

As the intelligence level of automobiles increases, the in – vehicle electronic systems are becoming more and more complex. Large – sized thick – copper double – sided flexible printed circuit boards can be used in the power systems, autonomous driving systems, entertainment systems, etc. of automobiles, meeting the requirements for high – current transmission and complex circuit layout. Meanwhile, their flexible characteristics can adapt to the complex spatial structure inside the automobile.

Power supply equipment

In high-power power supply board circuit boards, such as thick copper PCBs for charging piles, large-size thick copper double-sided flexible boards can withstand relatively large currents, effectively transmit electrical energy, and their large-size design can facilitate the integration of multiple circuit modules, improving the overall performance of power supply equipment.

Considerations for choosing large-sized thick copper double-sided flexible boards

Conductive performance

The design of thick copper enables the flexible board to have better electrical conductivity. However, different copper foil thicknesses and materials will affect the electrical conductivity. When making a selection, it is necessary to determine the appropriate copper foil thickness according to the specific current-carrying requirements.

Heat dissipation performance

Large-size thick copper double-sided flexible boards generate heat during the working process, and the heat dissipation performance directly affects the stability and lifespan of the flexible board. Thinner copper-clad laminates have relatively better heat dissipation performance, but being too thin may affect the reliability of the PCB. Therefore, factors such as the thickness of the copper-clad laminate need to be comprehensively considered.

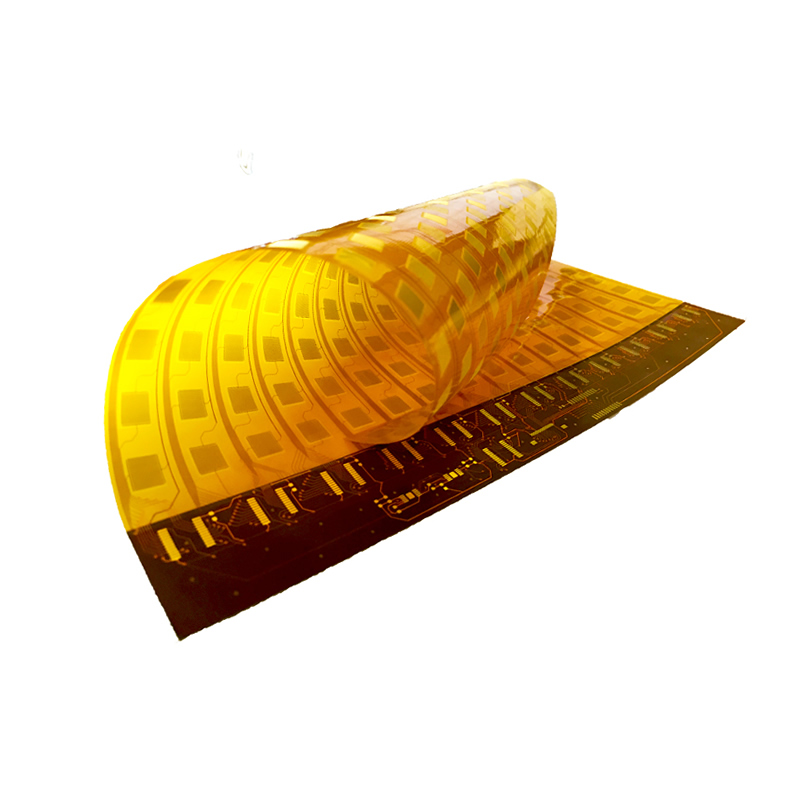

Reliability

In addition to the impact of heat dissipation performance on reliability, large-sized flexible printed circuit boards may face situations such as bending and folding during the processing and use. It is necessary to ensure that the flexible printed circuit boards have sufficient flexibility and mechanical strength to avoid problems such as oxidation, rusting, and breakage of the circuits.

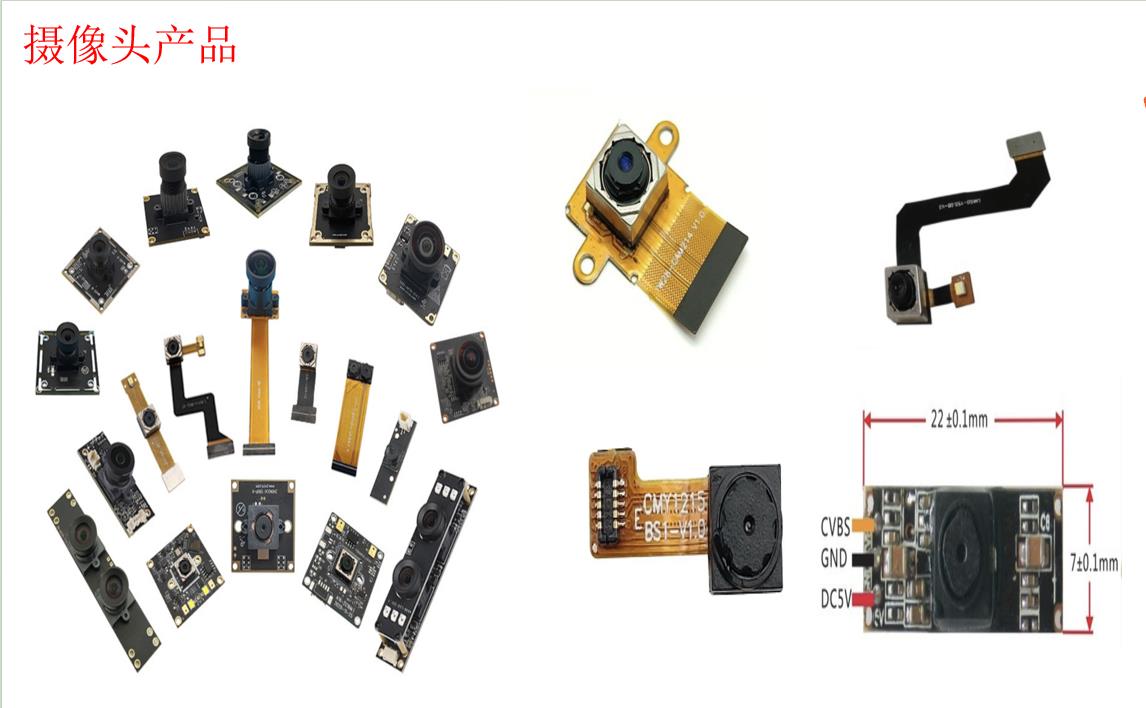

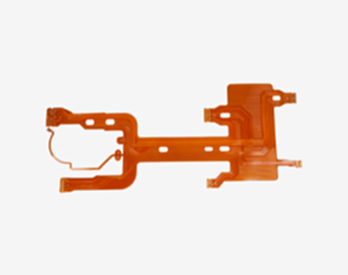

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

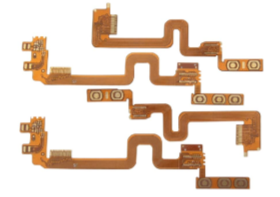

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

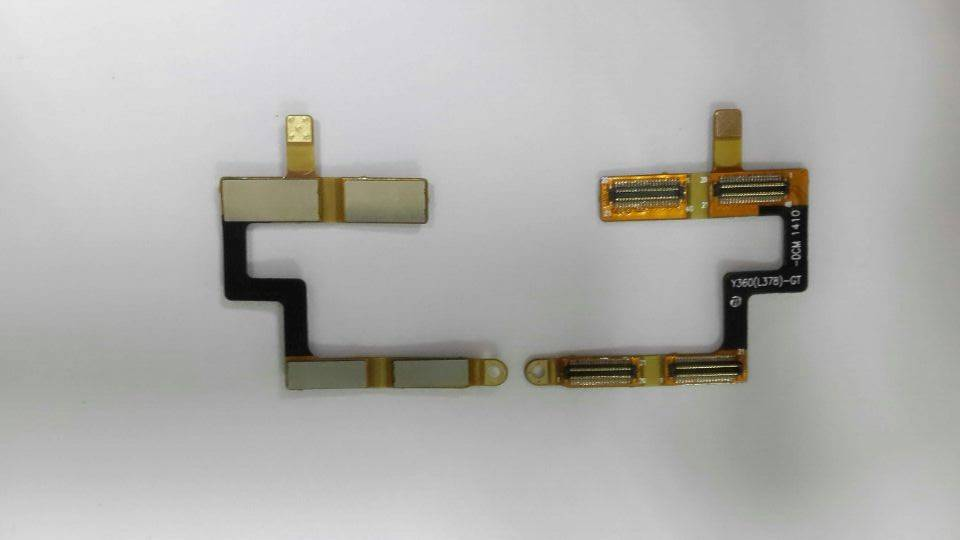

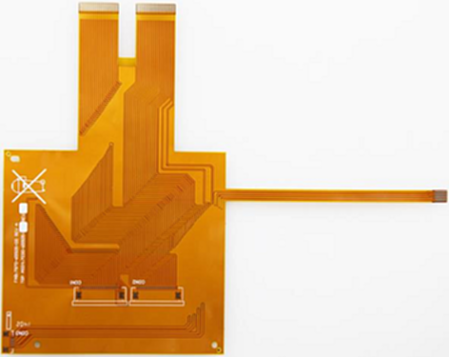

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More

Common knowledge of circuit boards: Composition and main functions of some parts of circuit boards

Common knowledge of circuit boards: Composition an…

Read More

Common knowledge of circuit boards: Composition and main functions of some parts of circuit boards

Common knowledge of circuit boards: Composition an…

Read More