-

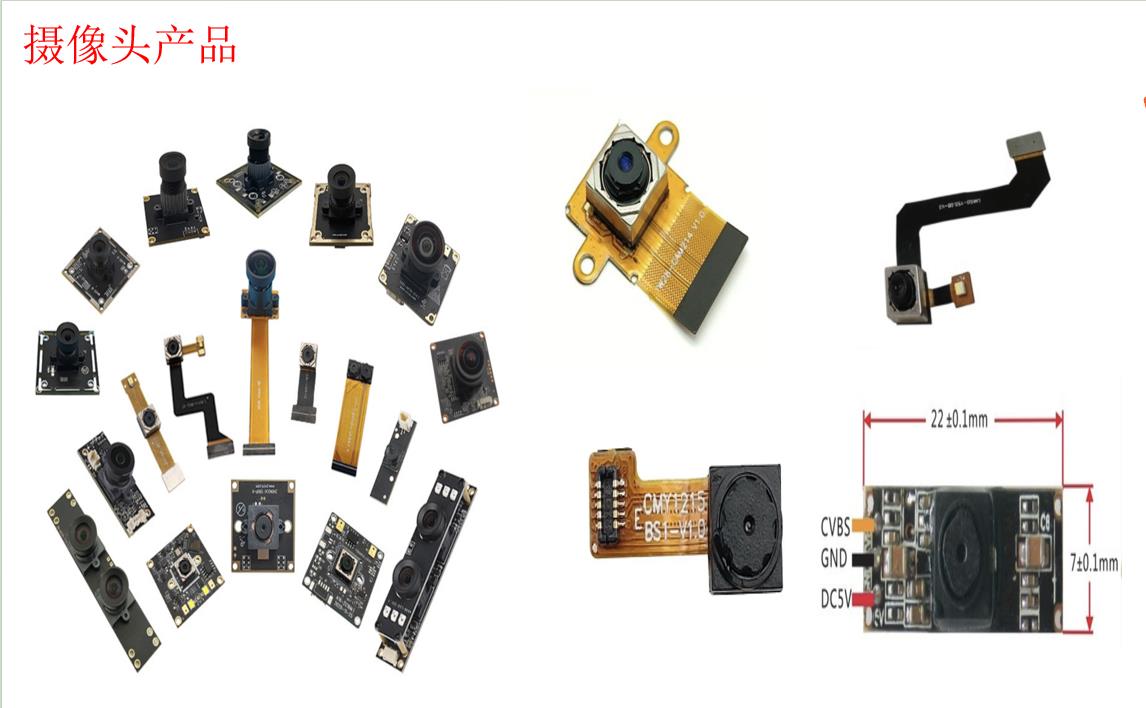

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

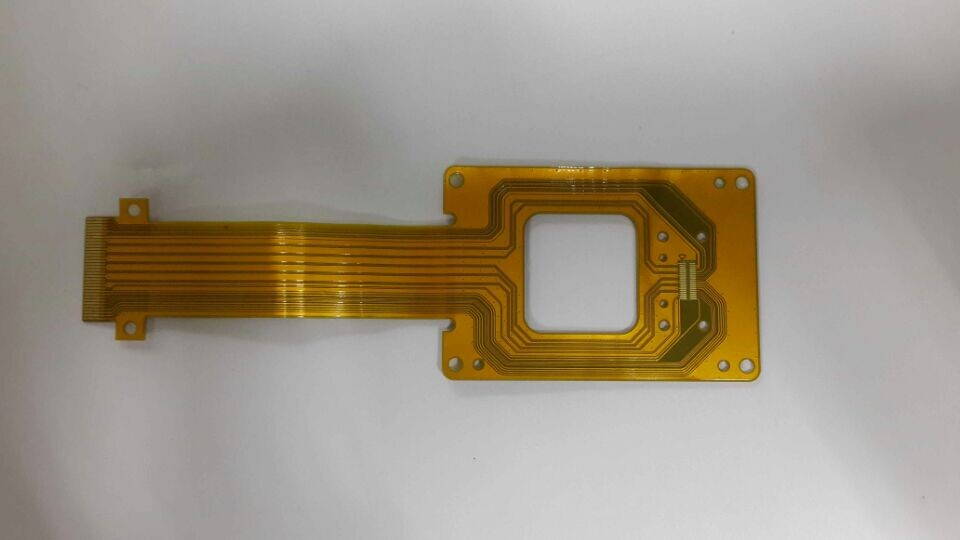

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

-

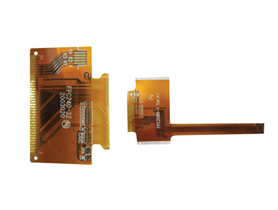

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

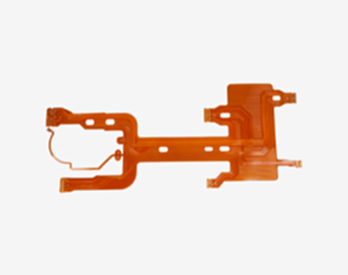

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

-

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

-

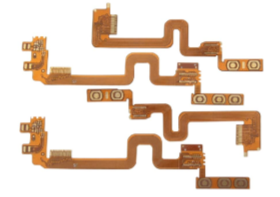

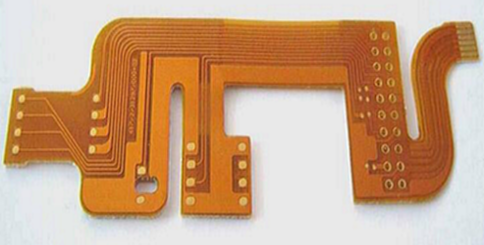

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

-

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

-

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

-

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

-

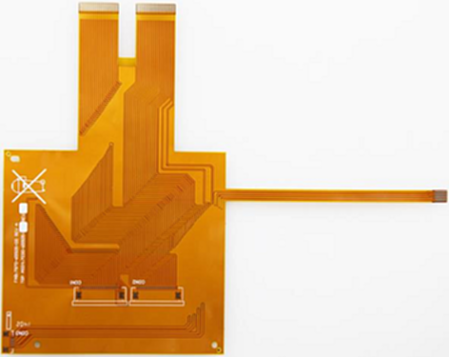

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

-

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

-

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

-

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

-

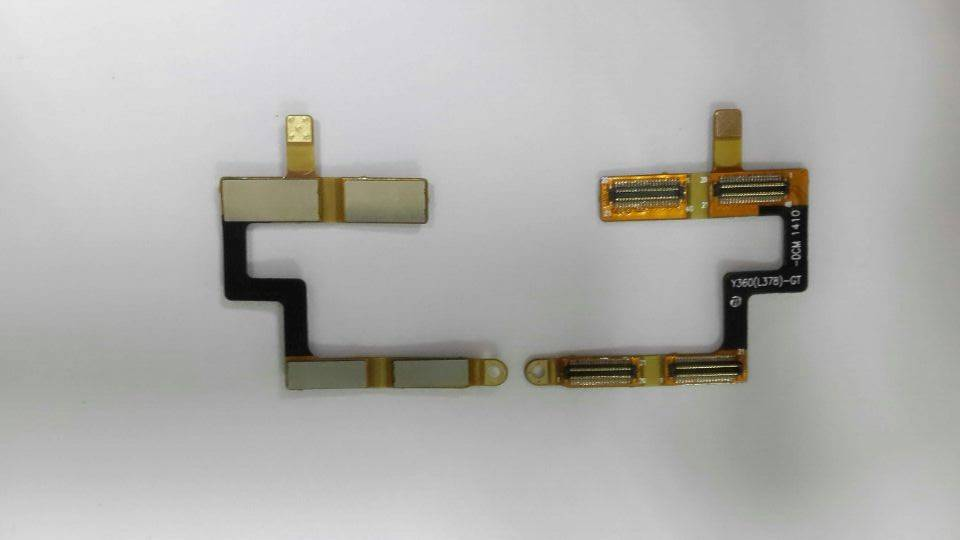

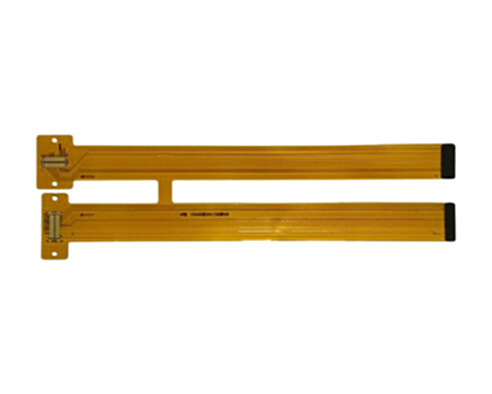

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

-

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

-

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

-

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

-

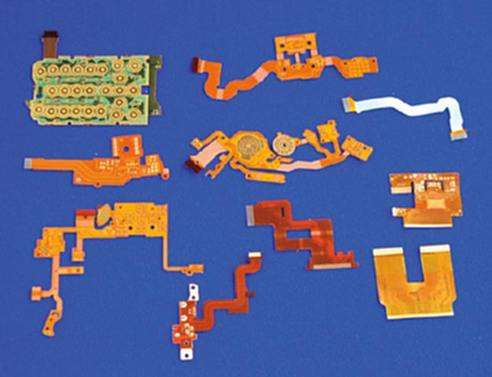

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

-

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

-

10-layer flexible FPC fingerprint circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer flexible FPC fingerprint circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

-

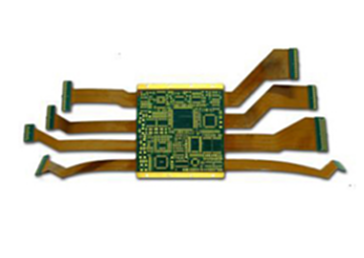

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

-

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More