Backlight plate FPC

Introduction to the FPC of the backlight panel

Definitions and Basic Concepts

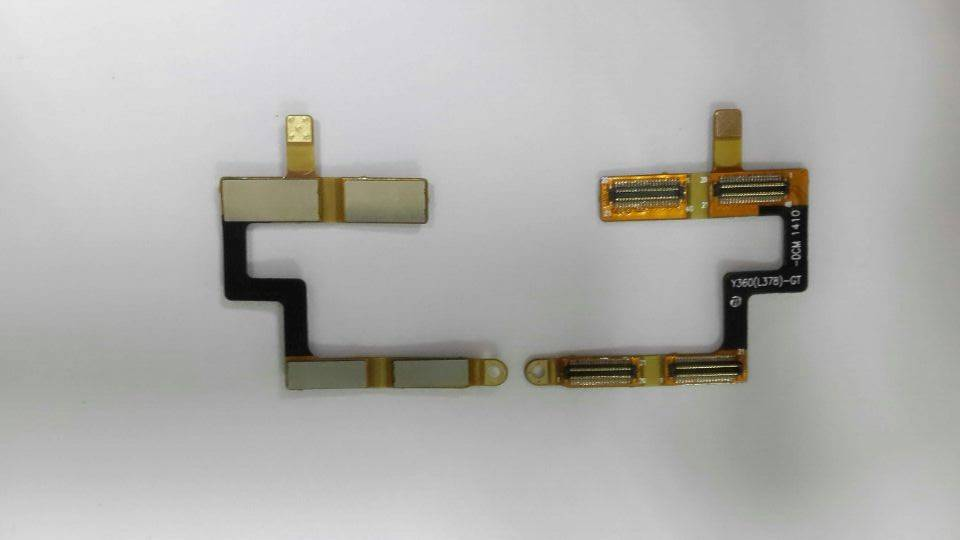

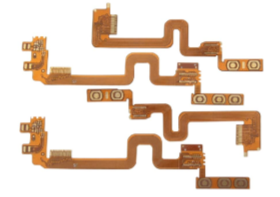

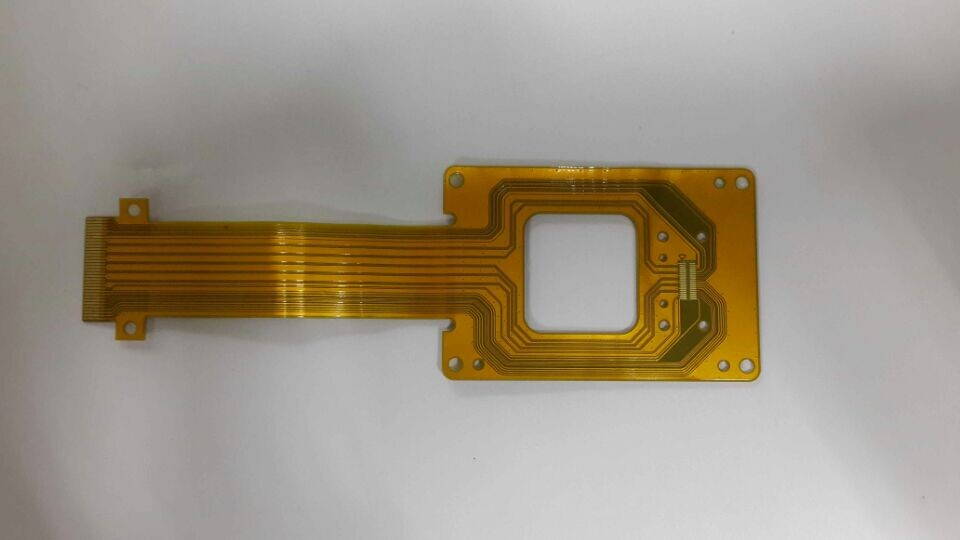

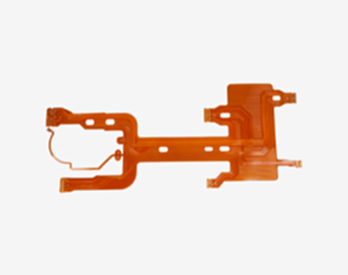

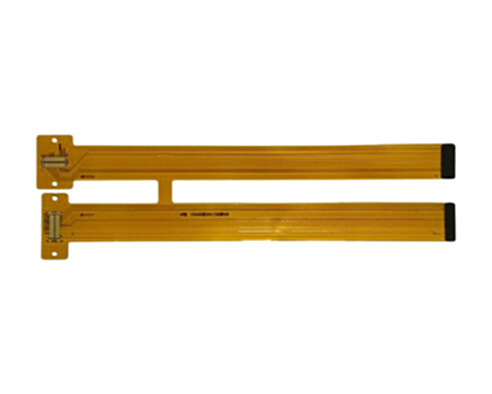

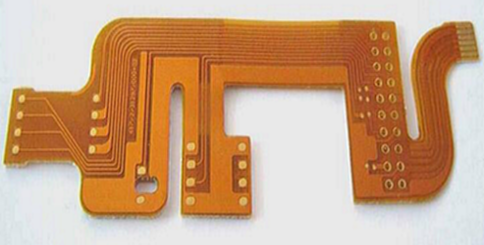

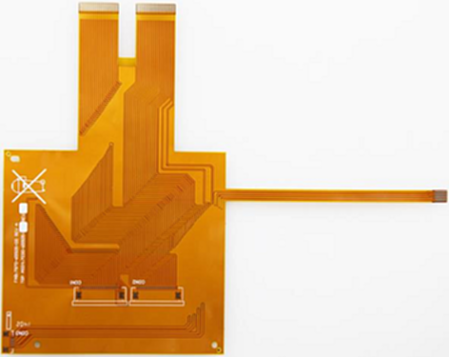

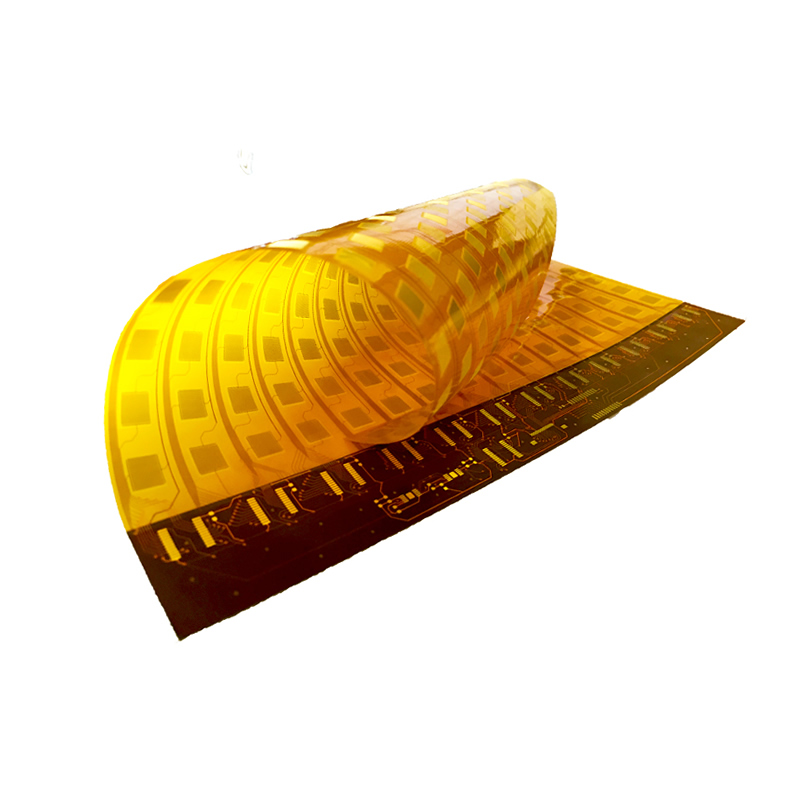

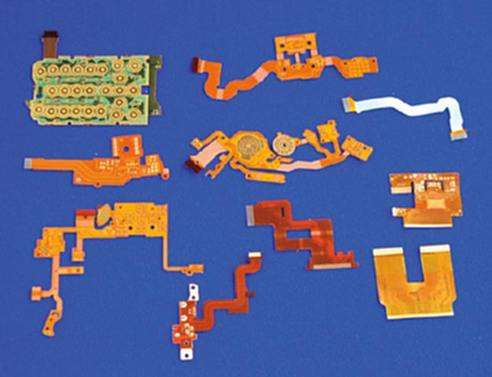

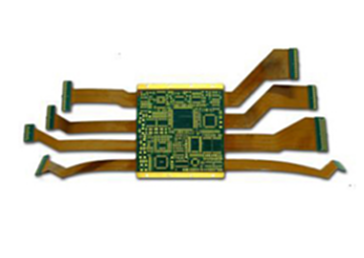

The FPC (Flexible Printed Circuit) of the backlight source board is a product applied in the field of backlight sources. FPC is also known as flexible circuit board, flexible printed circuit board, and flexible wiring board, abbreviated as flexible board or FPC. It is a printed circuit made of flexible insulating substrate, featuring high wiring density, light weight, thin thickness, etc.

Production and manufacturing

Manufacturers and production capabilities

- Zhonglian Hengsheng (Shenzhen) Electronic Co., Ltd. is an enterprise with many years of experience in the circuit board industry. It can produce mobile phone backlight FPC circuit boards, capacitive screen circuits, etc., and can carry out processing and customization. The boards it produces include single – sided paper boards, FR4 single – sided, double – sided and multi – layer boards, single – and double – sided aluminum substrates, single – and double – sided FPCs, high – frequency boards, etc. The company uses internationally automated circuit board production equipment and employs experienced professionals for management. It produces nearly 200,000 square meters of various precision single, double – layer and multi – layer circuit boards. The relevant production parameters of its FPC flexible boards are as follows: the maximum processing area is 500*500MM, the finished board thickness is 0.08 – 0.32MM, the minimum line width is 0.07MM, and the minimum line spacing is 0.07MM. In terms of production time, it takes 5 – 6 days for proofing, the small – batch production time depends on the quantity, and it takes 7 – 8 days for mass production.

Production process and surface treatment

-

Production process: It involves processes such as mold opening, sample making, and small – and large – batch production. The sample – making time is generally 3 days (24 hours for urgent orders), 6 – 10 days for multilayer boards (3 days for urgent orders), 4 – 6 days for small batches (depending on the quantity, about 10 days for multilayer boards), and 7 – 8 days for large batches (12 – 15 days for multilayer boards).

-

Surface treatment processes: There are processes such as tin spraying, lead-free tin spraying, rosin coating, OSP (Organic Solderability Preservative), gold plating, electroless gold plating, electroless silver plating, etc.

Technical patents

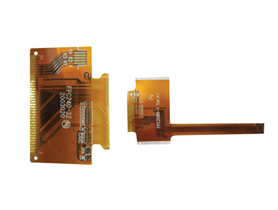

Truly Semiconductor Co., Ltd. has obtained a patent titled “FPC Structure of Backlight of LCM Module and LCD Screen” (Authorization Announcement No. CN222213162U, with an application date of April 2024). The FPC structure involved in this patent includes an LCD screen, a first FPC board, a backlight module, and a second FPC board. The first FPC board is arranged on the LCD screen, the backlight module is arranged on the LCD screen, and the second FPC board is arranged on the backlight module and welded to the first FPC board, with the first side and the second side being flush with each other. This solution can reduce the width of the FPC board of the LCD screen, increase the number of panel assemblies, and at the same time, reduce the clearance space required for the terminal device corresponding to the LCM module.

Welding device

There is a welding device for liquid crystal module and backlight FPC, which includes a pulse hot – pressing temperature control system, a CCD vision system, a first sliding table driven by a servo motor, a second sliding table driven by a servo motor, a sorting device for liquid crystal module and backlight FPC, a third sliding table driven by a servo motor, and a pulse hot – pressing head device. In the welding process of this device, the pressure of the hot – pressing head and the welding temperature of the hot – pressing head can be flexibly controlled through the cylinder and the pulse hot – pressing temperature control system, which is beneficial to the smooth welding of the liquid crystal module and the backlight FPC, improves the production efficiency, and solves the problems of the optimal welding process such as the alignment of the liquid crystal module and the backlight FPC, solder overflow, rosin application, solder thickness, and the control of the indenter temperature curve. At the same time, it leads the industry in terms of yield and efficiency.

Application fields

Backlight panel FPC products are widely used in fields such as electronic computers, communication products, household appliances, automotive supporting products, precision instruments, meters, aviation and aerospace equipment, etc. Moreover, these products are also widely exported to countries and regions such as Europe, America, Southeast Asia, South Korea, and Japan.