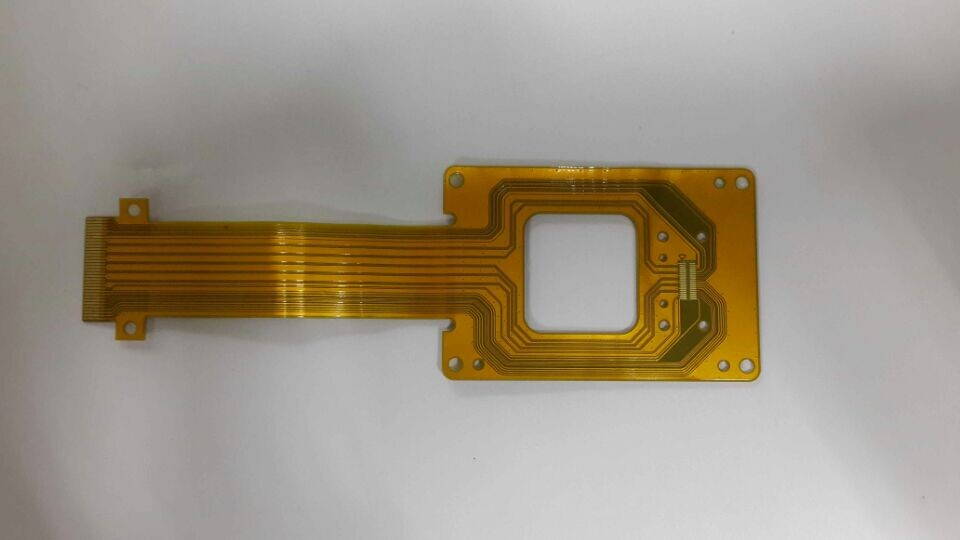

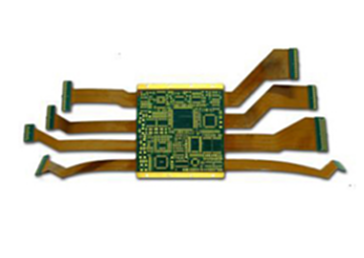

PCB type: FPC flexible circuit board

Number of layers: 6 layers

PCB thickness: 1.0mm

Surface treatment: Electro gold plating

Minimum line width/spacing: 3mil

Introduction to 6-layer Bluetooth earphone FPC flexible circuit board

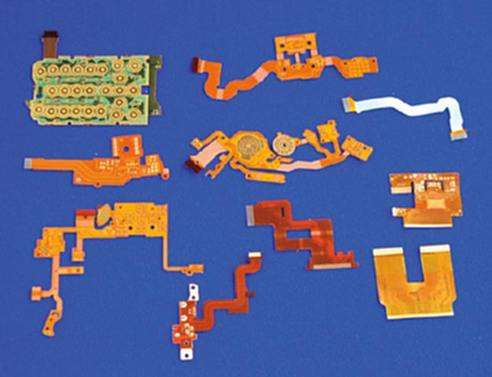

Product definition and structure

FPC (Flexible Printed Circuit) refers to the flexible printed circuit board, abbreviated as the flexible board. It is made by attaching a flexible copper-clad laminate (FCCL) and a flexible insulating layer with an adhesive (glue) and then pressing them together. The 6-layer FPC flexible board for Bluetooth earphones is a flexible circuit board with a 6-layer circuit structure used in Bluetooth earphones. Each layer of the circuit undertakes different functions, such as signal transmission and power distribution. The electrical connection between various electronic components inside the Bluetooth earphone is achieved through the interlayer connection.

Product features

Lightweight and portable

Using a flexible substrate, it has the characteristics of being thin and light, which helps to reduce the overall weight of the Bluetooth earphone and improve the wearing comfort. For example, the FPC flexible board of the Bluetooth earphone produced by Shenzhen Institute of Advanced Technology (Shenzhen) Technology Co., Ltd. has this characteristic.

Flexibility; Bendability

注:“Flexibility”较为常用,涵盖范围广,既可以表示物体的可弯曲性,也可用于形容规则、计划等的灵活性;“Bendability”则更侧重于强调物体本身物理意义上的可弯曲特性。具体使用可根据语境选择。

It has good bendability and can adapt to the complex internal spatial layout of Bluetooth earphones, ensuring the stability and reliability of circuit connections. This allows for greater flexibility in the design of Bluetooth earphones, enabling different shapes and structures.

High configuration line density

It can achieve high – density circuit design, allowing the electronic components inside the Bluetooth earphone to be arranged more compactly and improving the product’s integration and performance. Compared with single – layer or soft boards with fewer layers, the 6 – layer structure can accommodate more circuits and electronic components, further enhancing the functions and performance of the Bluetooth earphone.

Excellent electrical performance

Using high-quality conductive materials and advanced manufacturing processes, it has excellent electrical properties, such as low impedance and low noise, ensuring the stability and reliability of Bluetooth earphones when transmitting signals and data, thereby improving the sound quality and call quality.

Product application

Six – layer Bluetooth earphone FPC flexible boards are widely used in various Bluetooth earphone products, such as wireless earphones, sports earphones, noise – canceling earphones, etc. As an important bridge connecting various electronic components inside Bluetooth earphones, it undertakes key functions such as signal transmission, power distribution, and data exchange, ensuring the normal operation of Bluetooth earphones.

Product customization and services

The 6-layer Bluetooth earphone FPC flexible boards can be custom-designed according to the specific needs of customers, including circuit layout, size, materials, etc. In addition, the supplier will also provide professional technical support and after-sales service to ensure that customers receive timely and effective assistance during use.

Examples of market-related products

Baidu E-commerce Platform offers multi-layer rigid-flex printed circuit boards for sale. Among them, there is a 6-layer (6L) TWS earphone FPC with the brand Wuzhu PCB and the place of origin in Guangdong. Its minimum mechanical hole is 0.5mm, the base material is FR – 4, the minimum laser hole is 0.1mm, the minimum line width/line spacing (outer layer) is 0.075mm/0.07mm, the flame retardant property is V – 0, and the board thickness is 0.6mm. It can serve as a market product reference for 6-layer Bluetooth earphone FPC flexible boards.

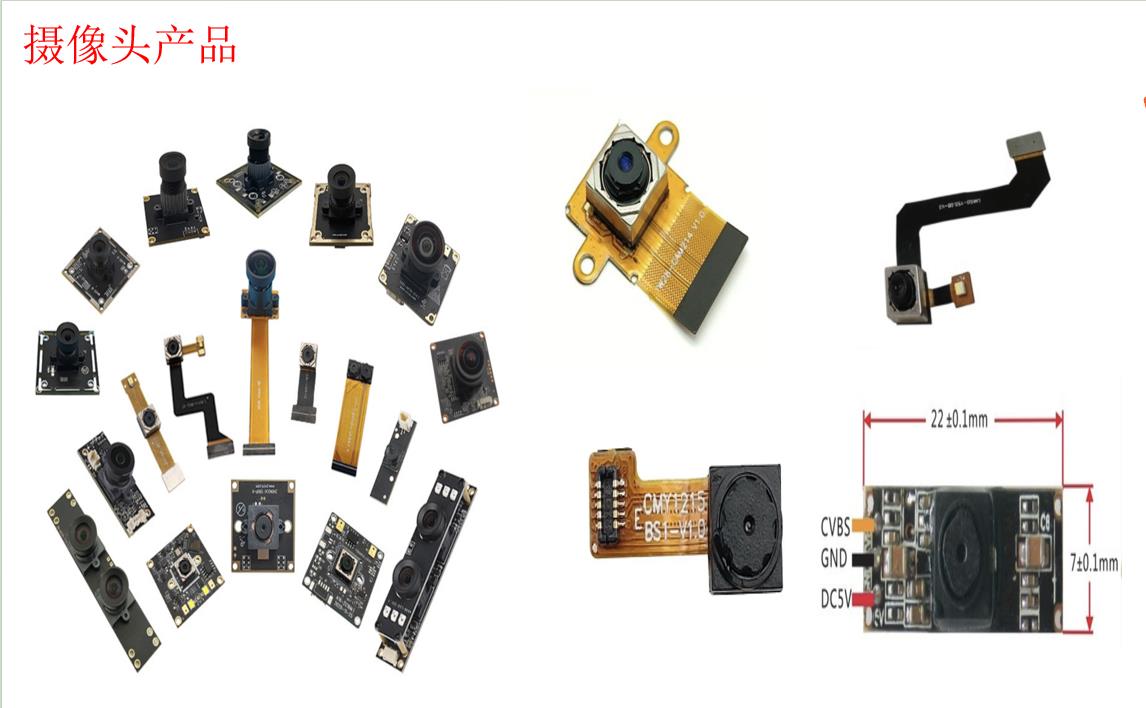

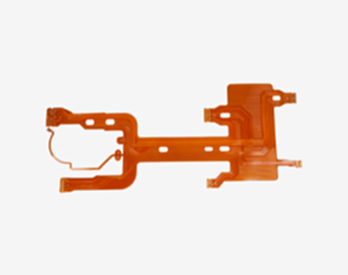

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Camera product FPC

Introduction to FPC for camera products Overview o…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Backlight plate FPC

Introduction to the FPC of the backlight panel Def…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Eight-layer FPC

Overview of eight-layer laminated board FPC The ei…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Side key FPC

FPC, which stands for Flexible Printed Circuit Boa…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

Impedance-controlled multilayer FPC

Impedance-controlled FPC is a special type of flex…

Read More

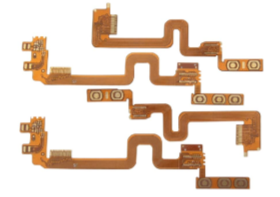

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

3-layer rigid-flex FPC PCB board

PCB type: FPC flexible circuit board Number of lay…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

Large size thick copper double-sided soft board

Introduction to large-size thick-copper double-sid…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

2-layer fingerprint recognition FPC

Introduction to 2-layer fingerprint recognition FP…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

Car brake light FPC soft board

Automobile brake light FPC flexible printed circui…

Read More

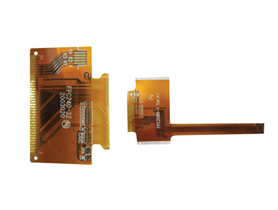

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

4 layer LCD display fpc flexible circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

6-layer Bluetooth headset FPC soft board

PCB type: FPC flexible circuit board Number of lay…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

Double-sided FPC gold immersion board

Double-sided FPC gold-plated board Double-sided FP…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

New energy lithium battery FPC protection plate

Overview of FPC protection boards for new energy l…

Read More

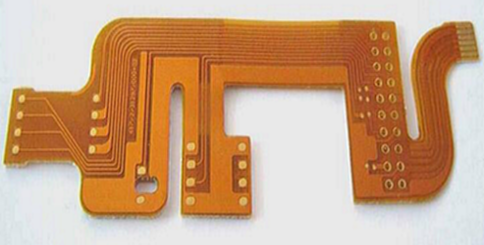

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

6-layer FPC circuit board

Introduction to 6-layer FPC circuit boards Product…

Read More

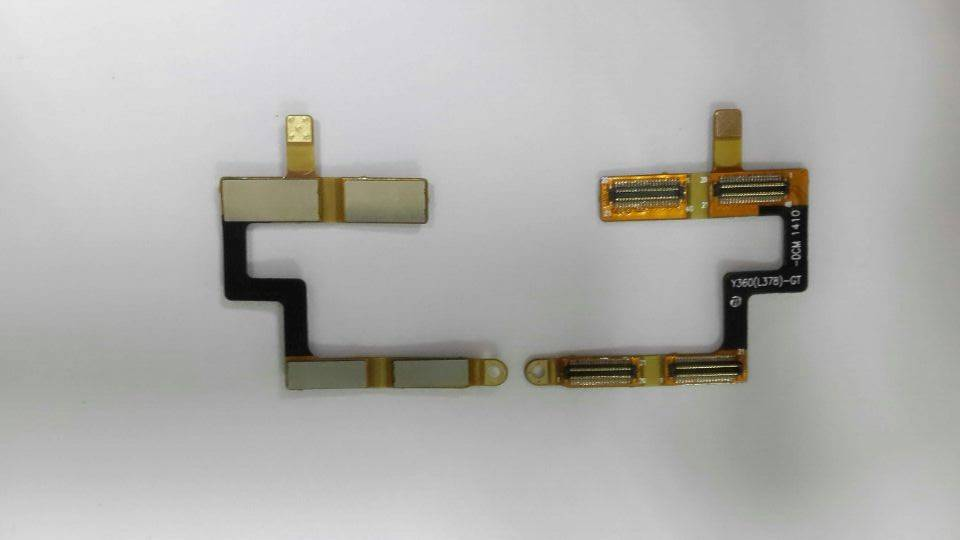

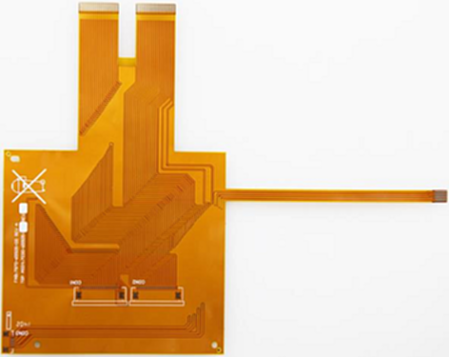

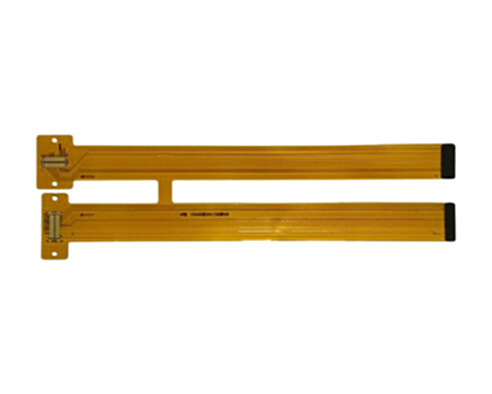

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Double-sided FPC ribbon cable

Overview of double-sided FPC cable Double-sided FP…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Ordinary single-sided FPC board production and sales

General single-sided FPC boards, namely single-sid…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

Impedance FPC production and sales

Product Overview FPC (Flexible Printed Circuit Boa…

Read More

10-layer flexible FPC fingerprint circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer flexible FPC fingerprint circuit board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

10-layer rigid-flex FPC HDI board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More

Medical equipment FPC interface board

PCB type: FPC flexible circuit board Number of lay…

Read More