1. Core Business

Customized FPC Design and Development

Rapid Prototype Support: 5-7 days delivery, supporting design iteration optimization.

High-Precision Design Capability: Minimum line width/spacing of 30μm, multilayer/rigid- board design.

Simulation Verification: Signal Integrity (SI), thermodynamic analysis to ensure reliability.

Flexible Circuit Board Production Manufacturing

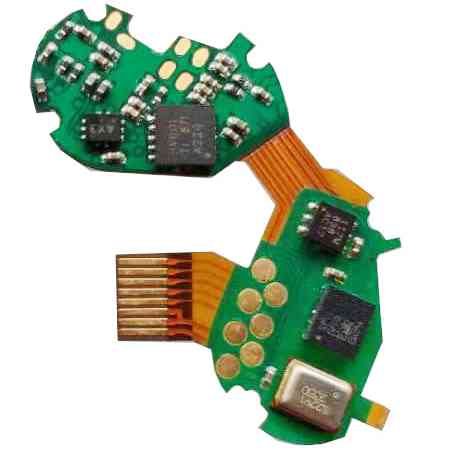

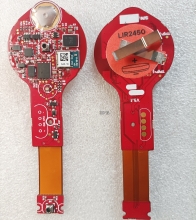

Full-Type FPC:

Single-sided/Double-sided/Multi-layer FPC

Rigid-Flex Board

Special Applications: High-frequency high-speed, high-temperature resistant, stretchable FPC

Advanced Processes:

Laser drilling (hole diameter ≤ 50μm), blind buried hole technology

treatment (soldering, tin plating, OSP, etc.)

Precise cutting (laser cutting with ±0.05mm tolerance)

-stop Value-Added Services

SMT Assembly: One-stop delivery of FPC component assembly.

Functional Testing: Impedance testing, conductivity testing, life testing (≥100,000 times).

Certification Support: Assist in passing UL, IPC, ISO 9001/3485 (medical), IATF 16949 (automotive) certifications.

2. Industry Solutions

Industry Application Sc Solution Highlights

Consumer Electronics Foldable screen phones, TWS headphones, smart wearables Ultra-thin design (≤0.1mm), dynamic life optimization

Automotive Electronics In-vehicle displays, BMS battery management, sensors High-temperature resistance (150℃ ), anti-vibration designMedical Equipment Endoscopes, wearable monitoring devices Biocompatible materials, micro-invasive flexible circuits

Industrial Control Robot joints, industrial sensors High, anti-electromagnetic interference (EMI)

3. Service Advantages

✅ Quick Response: 24-hour technical consultation, sample delivery as fast as 5.

✅ Cost Optimization: Flexible selection of domestic/imported materials, mass production cost reduction of 30% .

✅ Full Control: Real-time tracking production progress with ERP system, supporting customer factory inspections.

✅ Long-term Cooperation: Signing of NDA agreements, ensuring intellectual property rights and data security.

. Cooperation Process

Demand Communication: Fill in [Online Form] or contact sales to provide technical parameters.

Design Confirmation: Provide design drafts/Ger files, free DFM analysis.

Sample Verification: Quick prototyping and support for test optimization.

Mass Production: Fully automated production lines with a monthly capacity of square meters.

After-sales Support: Provide a dedicated account manager and lifetime technical consultation.